If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab A1 vs the Bambu Lab P1P

In this article, we’ll compare the Bambu Lab A1 and P1P to help you understand the differences between these 3D printers and help you determine which one is the better choice for you.

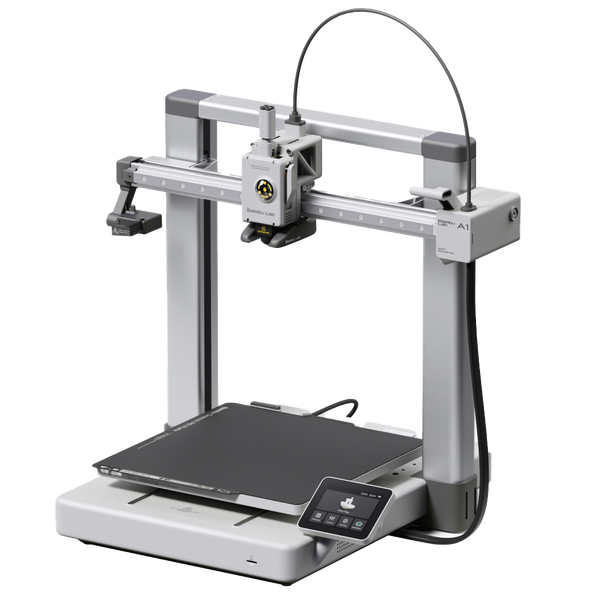

Bambu Lab A1

(~10.25 x 10.25 x 10.25 in)

Vs.

Bambu Lab P1P

(~10.25 x 10.25 x 10.25 in)

Since its release, the P1P has been Bambu Lab’s entry-level 3D printer, giving users the legendary print speed and quality of Bambu’s printers at a lower price than the premium Bambu X1-Carbon. But in the fall of 2023, Bambu Lab has released the A1 series, with two models that come in at a lower price than the P1P and more directly compete against 3D printers from other manufacturers.

What’s interesting about the A1 series–which consists of the standard-size A1 and the smaller A1 Mini–is that because they’re newer designs, they offer a few features that aren’t found on more expensive models such as the P1P. If you’re looking at buying a Bambu Lab 3D printer, the A1 in particular is an interesting comparison against the P1P, since the machines are fairly similar in price and offer the same build volume. It’s not immediately obvious which of these printers is the better buy.

We’re going to take a closer look at the features of the A1 and P1P and explain the differences between these two printers to help you decide which one is the better choice for you. We’ll start by going through the similarities between the printers.

Bambu Lab A1 and P1P Similarities

The A1 and P1P are similar in several ways, including their build volume, supported materials, software, and more. We’ll cover each similarity in this section.

Build Volume

The Bambu A1 and P1P both have a build volume, or maximum print size, of 256 x 256 x 256 mm (10.1” x 10.1” x 10.1”). This is the largest build volume offered by any of Bambu’s machines, and is slightly larger than average among consumer FDM 3D printers in this price range.

Supported Materials

Both printers have an all-metal hotend capable of heating up to 300°C and a heated bed capable of heating up to 100°C. This makes them capable of printing all standard 3D printing filament types, including PLA, PETG, TPU, PA, nylon, and more.

Some materials, such as ABS and ASA, require an enclosed build chamber to print larger parts, so they aren’t recommended materials for either the A1 or the P1P. If you do want to print one of these materials, you have a few options. On the A1, you can purchase or build an aftermarket 3D printer enclosure for the machine. On the P1P, you can purchase an upgrade kit from Bambu Lab to add an enclosure, or purchase the Bambu P1S instead, as that machine is essentially a P1P with an enclosure.

Print Bed Surface

The Bambu A1 and P1P both come with a textured PEI bed surface, which is one of our favorite print bed surfaces. PEI has great layer adhesion, but easily releases prints once the bed cools. It’s also durable and can be easily cleaned to prolong its life.

On both printers, the bed surface attaches magnetically to the bed, and can be removed and flexed to help remove stubborn parts after a print. This also allows you to easily replace the bed material, and Bambu Lab offers a few different options. For example, you can replace it with a smooth PEI bed from Bambu Lab’s store, which results in a glass-like finish on the bottom of printed parts. The A1 and P1P are both compatible with Bambu’s full lineup of 256mm beds.

Connectivity and Software

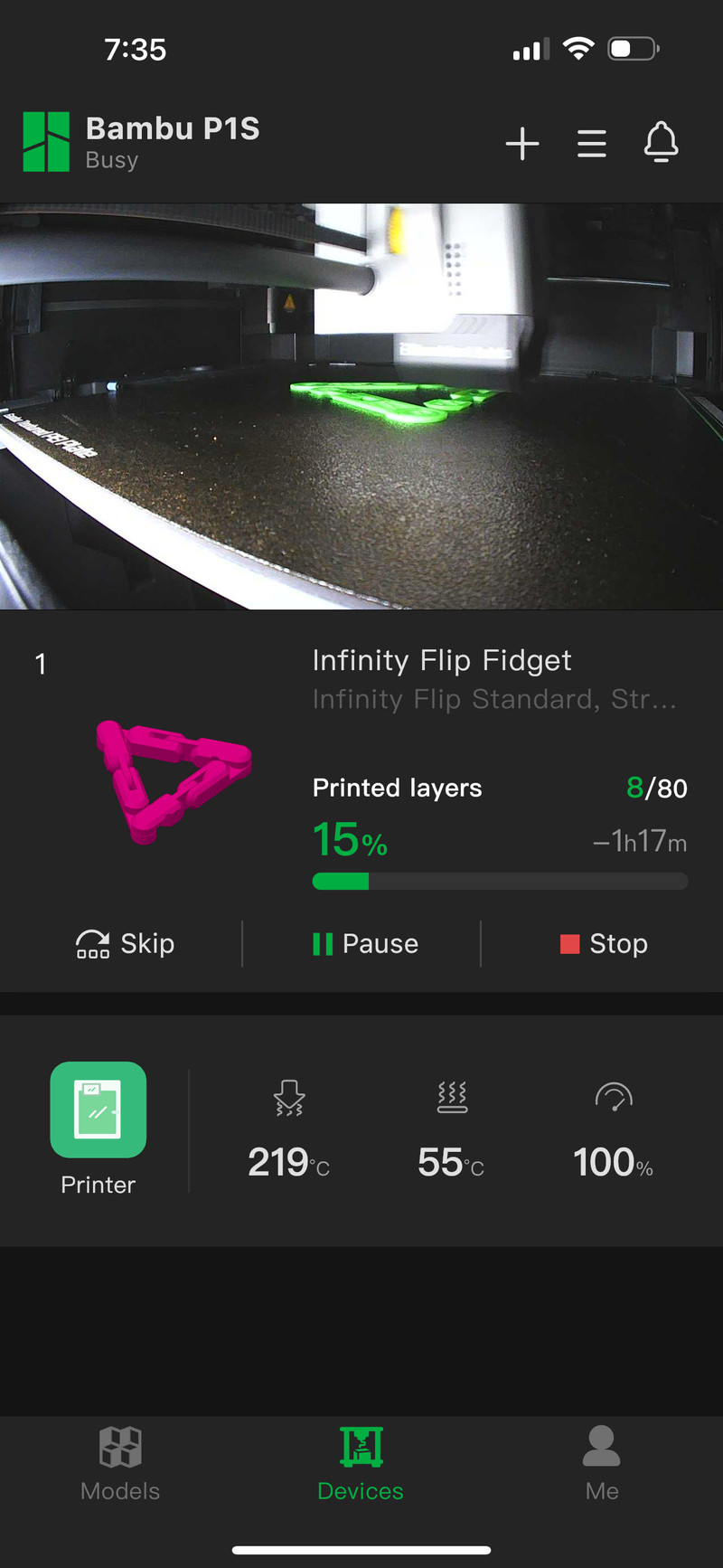

The A1 and P1P both include WiFi connectivity and work with Bambu Lab’s computer and phone apps, allowing you to control and monitor either printer remotely.

The Bambu Studio application allows you to control any Bambu printer from your computer, and you can also view the printer’s integrated camera. The Bambu Studio app also includes a slicer for preparing 3D models. You don’t have to use the Bambu Studio slicer if you prefer a third-party option such as Cura, but Bambu does caution that you can’t take advantage of all of the features of the printer (such as the optional multi-material capability, discussed later) without using Bambu Studio. If you’re using a third-party slicer, you can still use Bambu Studio to upload gcode files wirelessly to the printer.

The Bambu Handy smartphone app allows you to control the printer from your phone, which is a convenient feature for checking on an ongoing print. Similar to the computer app, you can view the printer’s camera. While the Bambu Handy app doesn’t allow you to slice and print your own models from your phone, it does give you access to Bambu Lab’s “MakerWorld”, which is a large directory of user-submitted models designed to print on Bambu 3D printers. You can select any of these models from the app and immediately begin printing it on your machine.

If you don’t wish to use the WiFi connectivity, both printers include a microSD card slot that allows you to load gcode files from a card.

Firmware Optimizations to Improve Print Quality

Like all of Bambu Lab’s printers, the A1 and P1P have a number of firmware features and algorithms that are designed to improve print quality, especially at higher print speeds. These features, such as pressure advance, vibration compensation, and input shaping, have started appearing on 3D printers in the past few years and do seem to make a noticeable difference in the print quality you can expect from these machines. Bambu Lab was one of the first manufacturers to include these features in an off-the-shelf consumer 3D printer.

Overall, you will see excellent print quality from all of Bambu’s printers, including the A1 and P1P. We don’t expect there to be any major quality differences between prints from these machines.

Automatic Bed Leveling

The Bambu A1 and P1P both include strain-based automatic bed leveling, which touches the nozzle to the print bed and uses a strain sensor to detect the contact. This is a very precise leveling system, and also calibrates the Z offset automatically. We’ve had great results from Bambu’s automatic leveling, and it eliminates one of the biggest pain points from older 3D printers.

Camera

The A1 and P1P both include an integrated camera, which is aimed at the print bed and allows you to visually monitor ongoing prints remotely. This is a great feature to include on a WiFi-connected 3D printer and is something we’d like to see other manufacturers adopt.

The camera on both printers is a “low framerate” camera that only updates every 2 seconds, meaning the camera view in the app is a static image rather than a smooth video. You do have the ability to create a timelapse of a print, which does play back smoothly and can be a fun feature.

Between the two printers, the camera in the A1 is a bit higher resolution–it’s 1080p, whereas the P1P’s camera is only 720p. For the purposes of monitoring a print, we don’t think this resolution difference is meaningful.

Bambu Lab A1 and P1P Differences

The A1 and P1P differ in some important ways, including their motion system, display, and multi-material printing support. We’ll cover each difference in this section.

Physical Design and Motion System

Perhaps the most apparent difference between the A1 and P1P is their physical design. The A1 is a Cartesian “bedslinger” machine, with the hotend moving left and right along an X axis gantry that also rises in the Z axis. The print bed moves forward and backward in the Y axis, which is where the “bedslinger” term comes from. This design is extremely common among consumer 3D printers, and the A1 does improve on the standard design by using a linear rail on the X and Y axes, which reduces vibration.

On the other hand, the P1P uses a CoreXY design, in which a system of belts and pulleys moves the hotend in the X and Y axes, while the bed only moves downward during the print. The CoreXY system is generally believed to offer superior performance since the fast bed movement of a Cartesian system can cause more vibrations, especially on taller prints. CoreXY is less common, but plenty of other 3D printers use a similar motion system. There are no reliability concerns with either design.

One other difference between these designs is that the CoreXY system completely contains all moving parts inside the P1P’s rectangular frame, while the Cartesian bedslinger design of the A1 has moving parts that protrude beyond the footprint of the machine. It’s important to account for this when fitting the printer into your workspace, although the printers are otherwise similar in desk footprint.

It’s hard to say whether this difference is meaningful. The CoreXY system on the P1P is generally believed to be a superior motion system, but the Cartesian system on the A1 is well-built and uses quality parts, which should close the gap between the two. The P1P probably edges out the A1 slightly in performance at high speeds, but it may not be enough for you to notice. The visual difference between the machines, or the ease of adding an enclosure to the P1P due to its physical design, may be a more important deciding factor.

Print Speed

Both the A1 and P1P advertise a maximum print speed of 500 mm/s, which makes them some of the fastest FDM 3D printers available. However, they do differ slightly in maximum acceleration, with the A1 being capable of 10,000 mm/s2 and the P1P capable of 20,000 mm/s2.

In real usage, we expect these printers to offer similar speeds, since the ability of any 3D printer to reach or maintain its maximum speed is highly dependent on the model being printed. However, the P1P’s faster acceleration and CoreXY motion system will allow it to get up to its maximum speed more quickly, which may reduce print time for certain models.

Display and Controls

The Bambu A1 includes a full-color graphical touchscreen controller, allowing you to easily view the printer status and control it when you’re directly in front of the machine. In contrast, the P1P uses a monochrome LCD display that can only display text, numbers, and icons, with an arrangement of physical buttons to control the printer.

While we are fine with the physical buttons, the display on the P1P feels rudimentary compared to a modern touchscreen display like the one on the A1. The display is a less critical aspect of a modern 3D printer since you can use an app for control, but we still like having an integrated display to quickly check the status of an ongoing print when we’re near the printer. The P1P’s display gets the job done, but feels out of place on that otherwise-premium printer. The A1 definitely wins in this category.

Flow Rate Sensor

The A1 includes a new sensor in the hotend to detect the flow rate of the filament as it extrudes through the nozzle. This allows the printer firmware to automatically calibrate the filament flow rate multiplier, which you may otherwise need to manually adjust when you switch filament types or brands.

This is a new sensor that we’ve only previously seen on the A1 Mini, and it’s an exciting addition to the A1. Although you can generally get good prints without adjusting the flow rate, configuring that setting properly will further improve the print quality. Having the printer set it automatically is a big improvement, and something we’d like to see come to other 3D printers in the future. The P1P doesn’t offer this sensor.

Enclosure Support

While neither printer includes an enclosed build chamber, the P1P’s rectangular frame makes it easy to add as an upgrade. Bambu provides free 3D models for you to print side panels for the P1P, or if you want a fully enclosed build chamber, you can purchase a P1P to P1S upgrade kit from the Bambu Lab store. On the other hand, the A1 wasn’t designed with an enclosure in mind, so the only way to enclose the machine is to build or buy an aftermarket enclosure to fit around the entire printer.

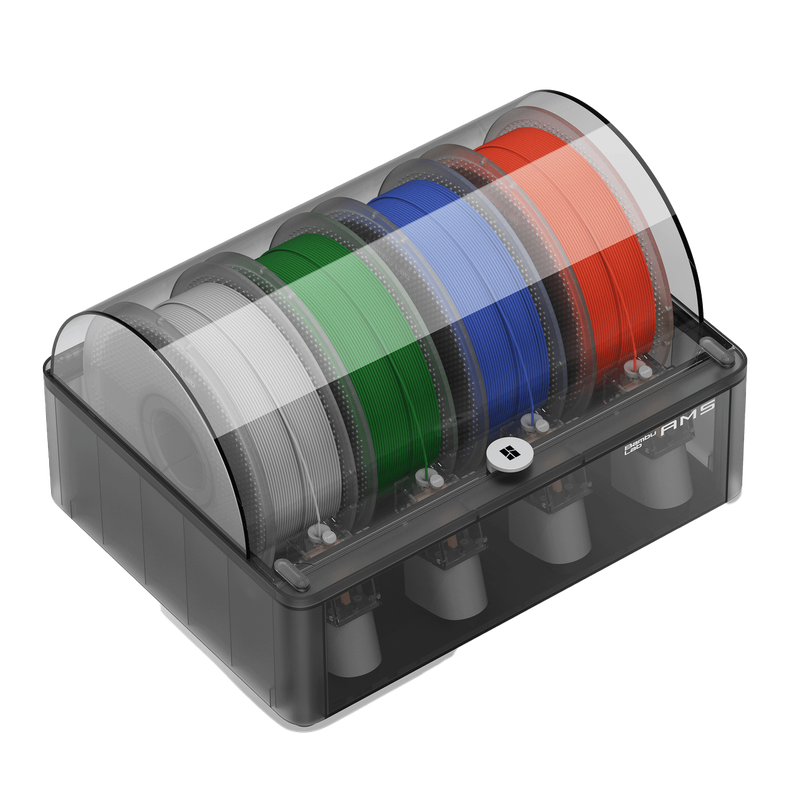

Multi-Material System

The Bambu A1 and P1P are both capable of multi-material or multi-color 3D printing through an optional add-on known as the Automatic Material System, but the two printers support different variants of this system.

The A1 uses Bambu’s newer AMS Lite system. This system supports up to four filament spools and typically sits next to the printer, although Bambu has shown a top-mount option to place the AMS Lite on top of the printer. The filament spools sit on pegs and all four feed to the hotend, resulting in a system that is mechanically simple, but a bit visually messy.

The AMS Lite has gotten limited runtime so far since it’s fairly new, but users have generally been pleased with the system, with some feeling that it’s more reliable than the older AMS unit used by Bambu’s other printers. Another advantage of the AMS Lite is that it’s cheaper than the other AMS. Right now, it’s not available separately and is only offered in a combo kit with the A1 from Bambu Lab’s store, but it’s surprisingly cheap to add on to the A1.

The P1P uses the Bambu AMS, which is Bambu Lab’s original multi-material system. This system also supports up to four filament spools, but the spools are stacked neatly side-by-side in an enclosed box that can sit either on top of or next to the P1P. This version of the AMS definitely has a cleaner appearance than the AMS Lite, but it’s significantly more expensive. Unlike the AMS Lite, it is available as a separate purchase from Bambu Lab. Bambu oddly doesn’t offer a combo kit of the P1P with the AMS, but you can buy a combo kit of the similar Bambu P1S with the AMS included.

With either of these systems, you will need to use the Bambu Studio slicer software to prepare models for printing. In addition to printing with multiple colors, the AMS and AMS Lite give you the ability to print with multiple materials, such as using breakaway support material for easier removal. You can also have the system automatically switch to another filament spool when one is depleted, allowing you to use the last bit of each spool.

Both the AMS and AMS Lite seem to be good implementations of multi-material printing, and offer a capability that you can’t get on most other 3D printers. Between the two, we prefer the clean look of the P1P’s AMS, but it’s hard to beat the affordable price of the A1 and AMS Lite combo. It also seems likely that Bambu Lab has learned some lessons from the original AMS design, which may result in better reliability from the AMS Lite on the A1.

Noise Level

While 3D printers are not silent machines by any stretch, many modern printers include control circuitry which greatly reduces motor noise, making the cooling fans the loudest part of the printer. This results in a consistent white noise that is easy to tune out. The Bambu A1 includes these silent motor drivers, and has a fairly low noise level as a result.

On the other hand, the Bambu P1P is not a particularly quiet machine. While it doesn’t exhibit the odd singsong motor noise of some old 3D printers, it’s surprisingly loud during printing, which may be a downside if you’re in the same room as the printer or have it located in a shared space.

It’s worth noting that as of this writing, Bambu Lab has just released updated firmware for their flagship X1-Carbon model that substantially reduces the printing noise. There are rumors that Bambu Lab is currently testing similar firmware for the P1P and P1S models, which may alleviate this concern. When that update releases, we’ll update this article with our thoughts on whether it’s an improvement.

—-

Bambu A1 vs P1P: Which Should You Choose?

As you can see, the Bambu A1 and P1P have some complicated tradeoffs in terms of their design and features. It’s surprisingly difficult to judge which machine is better, despite the P1P’s higher position in Bambu Lab’s lineup.

In our opinion, the Bambu A1 is the better choice in most cases. It’s a newer design that includes some features not found on the P1P, such as the touchscreen display and flow rate sensor. It’s also cheaper than the P1P, while still offering the same build volume and nearly the same print acceleration. It can print all of the same material types as the P1P, and the AMS Lite multi-material add-on is much cheaper than the equivalent AMS for the P1P. You can buy the combo kit of the Bambu A1 with the AMS Lite for approximately the same price as the Bambu P1P by itself.

On the other hand, the P1P gives you the more capable CoreXY motion system, a physical design that lends itself well to being enclosed, and slightly faster print acceleration. It’s also a more proven printer than the just-released A1, and has been a popular choice in the 3D printing community since its release. Similar to the A1, it does support multi-material printing with an add-on, and its version of the AMS has a cleaner appearance than the AMS Lite on the A1.

You can view both printers on Bambu Lab’s site using the links below, or continue scrolling on this page to see a side-by-side feature comparison between the two printers.

Click here to view the Bambu Lab A1 on the Bambu Lab website.

Click here to view the Bambu Lab P1P on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: