If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Prusa MK3S+ vs the Prusa MK4

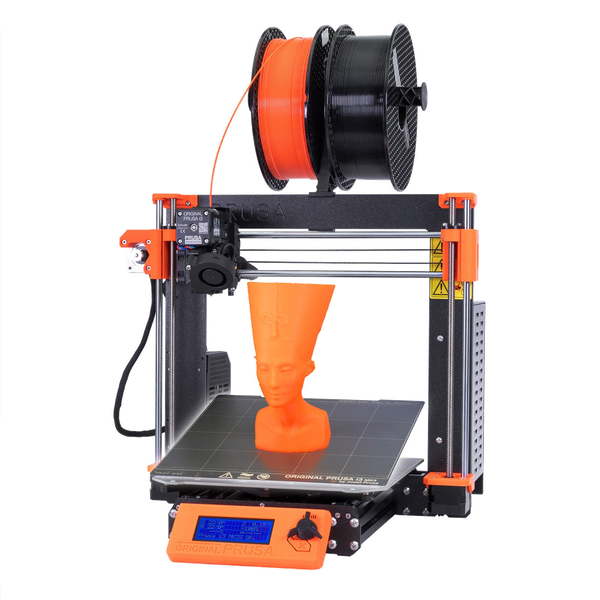

Prusa MK3S+

(~8.25 x 8.25 x 10 in)

Vs.

Prusa MK4

(~8.25 x 8.25 x 10 in)

In the time since it went on sale in early 2018, the Prusa MK3S+ 3D printer has become a trusted choice of the 3D printing world. At the end of March 2023, Prusa Research announced the next model, the Prusa MK4. The newer model aims to achieve all the same reliability and quality of the MK3S+ while adding several features focused on improving user experience, print speed, and print quality performance. While Prusa keeps the basic design cues of the MK3S+ in the MK4, the manufacturer made several changes to the physical hardware, electronics, and software of the printer.

We will first discuss the aspects of the Prusa design that remain unchanged between the MK3S+ and MK4, then move on to the design changes Prusa made for the MK4, and finally give a quick overview of the buying options for the two printers and the upgrade kits that Prusa offers.

What’s Similar Between the Prusa MK3S+ and MK4?

The MK4 offers a wide array of changes to the MK3S+ design; however, many aspects of the design remain unchanged. Both printers feature a Standard Cartesian drive system, a direct drive style extruder design, and an all-metal hot-end capable of temperatures up to 290 ℃. They also both feature a magnetic heated print bed, capable of reaching 120 ℃, with removable PEI spring steel print sheets included. Both printers are capable of automatic mesh bed leveling, which is the process of measuring and accounting for very small variances in the print bed surface in order to print each layer to accurately match the Z height of the print bed.

Although they use different methods, the MK3S+ and MK4 both have a filament sensor that can detect when filament runs out and pause a print until it is reloaded. Both printers utilize a reliability feature called Power Panic, which allows you to resume a print if power to the printer is suddenly lost, and slightly raises the nozzle to prevent damage to the print. Finally, the printers do have a very similar build volume; the MK3S+ is capable of 250 x 210 x 210 mm, and the MK4 just barely increases the available Z-dimension space with capabilities of 220 mm. This small change in printable Z height is just the beginning of the updates that come with the MK4 model.

What Is Different Between the Prusa MK3S+ and MK4?

The Prusa MK4 includes many updates over the MK3S+. In this section, we’ll describe each of the changes and explain how they affect the printer’s capabilities.

Structural Changes

Stiffness for stability in faster printing is an emphasis for Prusa in the design of the MK4. The MK4 includes a newly designed frame that is die cast aluminum with a honeycomb structure for rigidity. The previous MK3S+ frame is laser cut aluminum, offering a different appearance and slightly lower rigidity. All of the 3D printed components on the printer were slightly modified to either accommodate new hardware or improve the robustness for the Z and X axis assemblies. Additionally, the Z axis rods on the MK4 are thicker and more rigid; up to a 10 mm diameter from the 8 mm standard on the MK3S+.

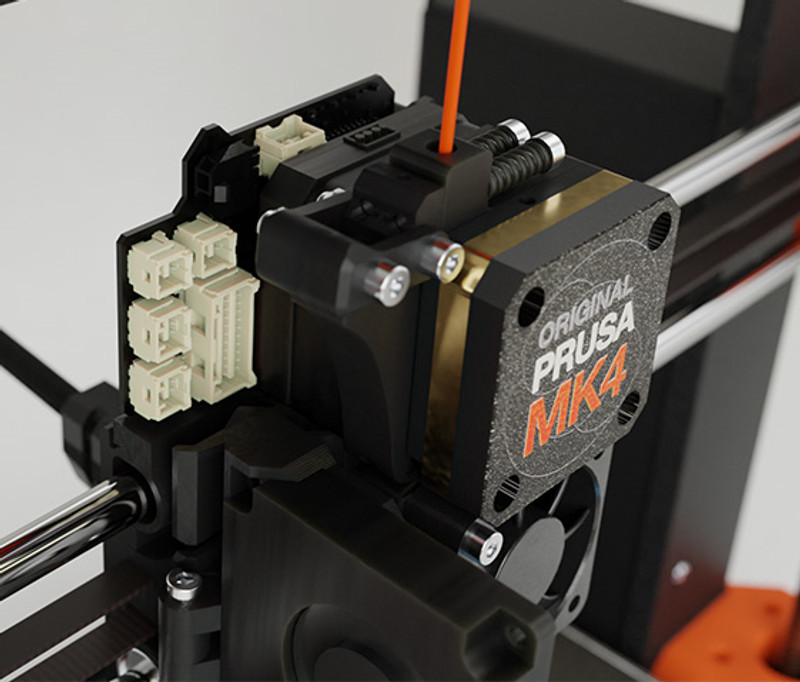

Extruder Updates

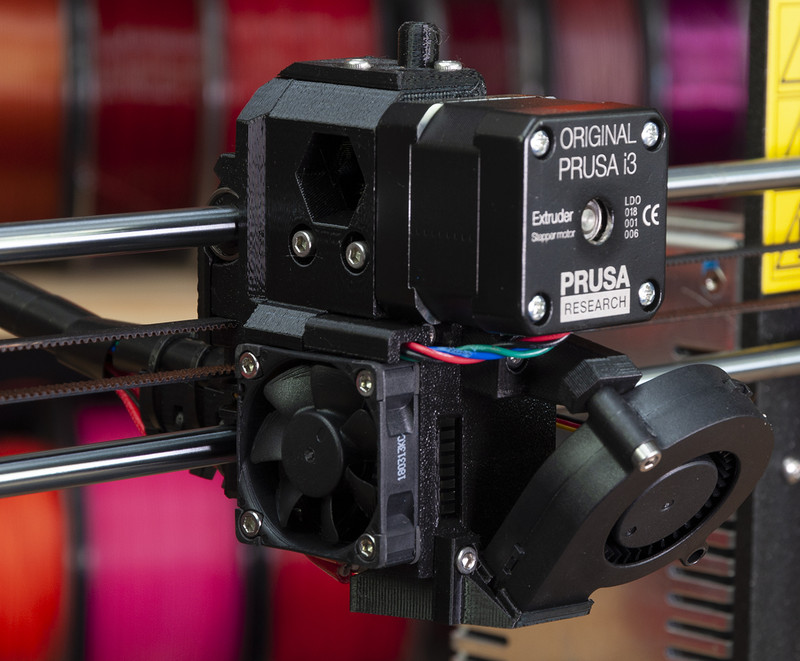

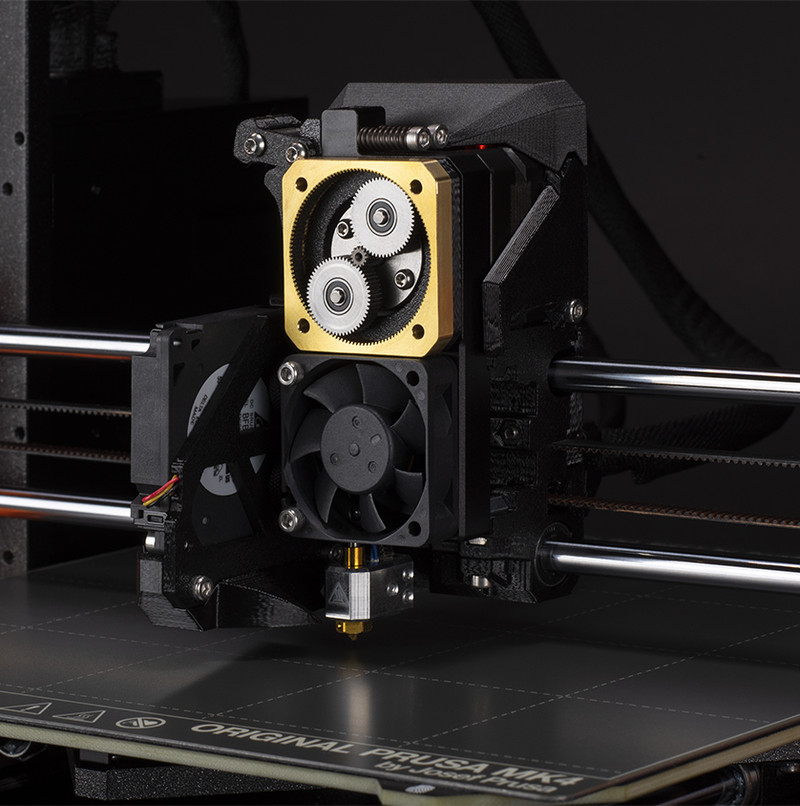

Drive System

The extruder design is quite different on the Prusa MK4. While both printers are direct drive, the MK4 features a 10:1 planetary gearbox with a “pancake” motor, while the MK3S+ has no gearbox but uses a larger motor. The pancake motor is capable of less torque than the larger motor in the MK3S+, but the added gearbox reduction compensates for this difference and allows for a design that brings the center of gravity of the extruder closer to the X axis. This helps to keep vibrations at bay when printing at faster speeds.

Sensors

The MK4 extruder is equipped with some different sensors than the MK3S+:

- Hall sensor to detect filament loading, replacing the MK3S+ infrared sensor

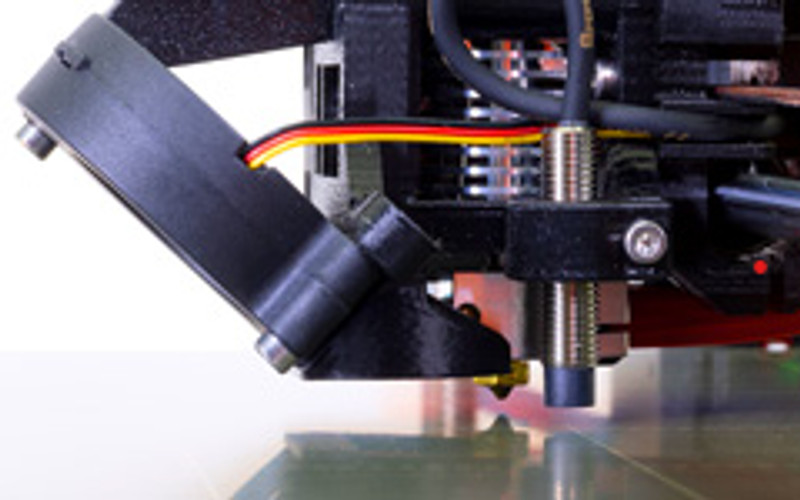

- Load cell sensor that is used to measure the distance between the print nozzle and print sheet along the Z axis, replacing Prusa’s PINDA sensor

The MK4’s load cell sensor offers an advantage over the PINDA as it is more precise and eliminates the need for user calibration of the Z height for the first layer of a print. With the MK3S+, you would need to calibrate the nozzle height when setting the printer up, requiring you to watch the extruder print a zig-zag pattern, then manually make adjustments to the Z height of the nozzle. This is crucial so that the first layer of the print will properly stick to the print bed without building up bunches of filament around the nozzle. With the new extruder on the MK4, this calibration process is now automatic; additionally, the MK4 only calibrates for the print area and not the entire sheet, saving some time in printing.

Cable Management and Nozzle Changes

The extruder on the MK4 features the addition of a breakout board on the extruder assembly in conjunction with a swappable nozzle design. For the MK3S+, if you want to swap out your nozzle on the hotend, you have to disassemble a large portion of the extruder and cut and retie zip ties for your cable routing, as the hotend cables all route to the mainboard at the side of the printer. The MK4 extruder design provides the opportunity to more easily and quickly swap a nozzle from the hotend by unscrewing the 2 thumb screws securing the nozzle and disconnecting the hotend cables from the breakout board that resides on the extruder itself.

Electronics and Software Features

Mainboard

Prusa designed a completely new mainboard for the MK4. On the outside, the mainboard enclosure has been changed to a metal part, whereas on the MK3S+ it was a 3D printed plastic enclosure. The Einsy 8-bit board that controlled the MK3S+ is replaced with Prusa’s new xBuddy 32-bit board. This new board includes all the reliability features of the Einsy, and adds overcurrent protection for the extruder and heatbed along with ambient and heatbreak thermistors to improve temperature control while printing and safely shut the heat off if the printer is overheating.

Firmware

The new firmware on the 32-bit MK4 utilizes processes called input shaping and pressure advance to improve print quality. Input shaping actively cancels out vibrations that may occur during printing to keep each layer as accurate as possible, while pressure advance is able to predict pressure in the nozzle to account for extrusion speed changes during faster printing and keep the filament extruding at the rate required. Both of these processes allow the MK4 to print much faster than the MK3S+ without sacrificing any print quality.

Utilizing the ports on the new MK4 mainboard, the new firmware includes default compatibility with Wi-Fi, Ethernet, remote printer management software (Prusa Link), and USB-A/USB-C connections to a PC. The MK3S+ is only capable of a USB-A connection to a computer. The MK4 can utilize a USB flash drive to load gcode when printing offline, while the MK3S+ requires use of an SD card to load gcode when not connected to a computer.

Display and UI

The UI is an area where Prusa has been behind the curve of other manufacturers. The MK4 does have a color LCD display with a new interface that includes features such as one-click printing, customizable GUI, and a separate RGB LED array that indicates the status of in-progress prints. However, the newer screen is still controlled using a knob, and does not have a touch interface. This is still a big improvement over the MK3S+, which has a monochromatic LCD screen with fewer built in features directly accessible on the printer.

Axis Stepper Motors

Finally, the MK4 uses a more precise stepper motor for the print axes. The MK3S+ uses stepper motors that have a step angle of 1.8 degrees, while the MK4 has a step angle of 0.9 degrees. Prusa claims that this eliminates a phenomenon known as Vertical Fine Artifacts, which are very small vertical lines across layers that can be visible on many 3D prints.

Summary

The Prusa MK4 is in all aspects an iteration on the design of the MK3S+. It can achieve everything the MK3S+ does, while adding additional integrated printer control features, a more user-friendly interface, and quicker, more accurate hardware into the mix. Perhaps the most striking resultant performance difference of the design iterations from the MK3S+ to the MK4 is the ability to complete prints much more quickly with higher print accuracy all while making less noise. Print speed is an area where the MK3S+ suffers compared to other printers on the market; the MK4 steps confidently into the fray with a blazing fast print speed.

The 3D printer benchmark model boat “benchy” prints on the MK3S+ (at draft resolution) in approximately 81 minutes, while the MK4 manages to complete the print in 20 minutes. The MK4 is far from the fastest printer on the market, but it does offer a significant improvement to speed over the MK3S+, and holds its own with the newer generation of faster printers from other manufacturers like Bambu Lab.

The biggest disadvantage of both of the Prusa printers is certainly their high cost. Prusa owners enjoy the online community, brand maturity, and open-source mentality Prusa offers, but the pricing of similarly equipped printers, such as the Bambu P1P, beats the Prusa MK4 when it comes purely to getting the most features for your money.

Pricing and Upgrade Options

The MK4 can be purchased as a kit or fully assembled (both links go to the Prusa website, which is the only place that sells the printers). However you’ll pay a heavy premium for the assembled version. The MK3s+ is substantially lower in price, and has been significantly discounted with the release of the new version.

If you already own a MK3S+ printer and are looking to upgrade, there are several options available that allow you to re-use some MK3S+ hardware while gaining some of the features of the MK4. For each of these kits, you must print the plastic parts for the upgrade yourself before disassembling your printer. All of these links go to the kits on the Prusa website:

- The cheapest is the MK3.5 upgrade kit, which gives you the new mainboard with all its features as well as the color LCD screen; this level does not include the new extruder design.

- The next step up is the MK3.9 upgrade kit, which adds in most of the new hardware from the MK4 aside from the higher precision axis motors.

- The full upgrade kit that will upgrade the MK3S+ to a complete MK4, including the high precision motors for around $580. The parts reused from your MK3S+ would just be the frame, printer bed, and power supply.

Final Thoughts

If you’re looking to go with the Prusa brand, the MK4 is an excellent choice for a high quality printer at that price point. Your choice will depend on your situation and use case, but in general we would say that the added functionality of the MK4 is worth the additional cost, especially if you opt for the kit to assemble yourself as it is only about a $150 difference to the MK3S+.

If you happen to already have a MK3S+ and are looking to upgrade on a budget, we would recommend the MK3.5 upgrade kit. Again, your use case dictates what is important for your printer, but with the more expensive upgrade kits, you begin to approach price ranges that may justify simply buying the standalone MK4 kit to use in addition to your MK3S+!

Click here to view the Prusa MK3S+ on Prusa3d.com.

Click here to view the Prusa MK4 on Prusa3d.com.

You can find a side-by-side comparison of the specifications for these two printers in the table below: