If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Creality K1 Max vs the Bambu Lab X1 Carbon

In this article, we’ll be comparing the Creality K1 Max to the Bambu X1-Carbon (also known as the X1C). These two printers are priced similarly and offer a similar feature set, but have some key differences that may make you more inclined to choose one printer over the other. We’ll cover all of the similarities and differences between the machines to help you decide which one is the better choice for you.

Creality K1 Max

(~12 x 12 x 12 in)

Vs.

Bambu Lab X1 Carbon

(~10.25 x 10.25 x 10.25 in)

Bambu Lab entered the 3D printing market in 2022 and quickly made an impression with their sleek designs and unprecedented print speeds. The Bambu X1-Carbon was one of their first models, and is still a popular choice of 3D printer for its advanced features, print quality, and speed.

Creality has been around for several years longer than Bambu Lab, and has maintained a strong position in the 3D printing market, with a wide range of popular machines at all price points. But the Bambu X1-Carbon presented Creality with a new threat in the premium 3D printer space. It’s taken Creality some time to respond, but in 2023 they’ve released the Creality K1 and K1 Max, two new 3D printers offering a feature set more in line with Bambu Lab’s machines.

We’ll start by covering the similarities between the printers.

Similarities Between the Creality K1 Max and Bambu X1 Carbon

The Creality K1 Max and Bambu X1C have several similarities, including their physical design, material capabilities, and automatic calibration systems. We’ll cover all of the similarities in this section.

Enclosure and Motion System

Both printers are built with a metal rectangular frame with an enclosed build chamber, and both use a CoreXY motion system that optimizes for higher print speed. In general, the printers have a very similar appearance, and both look sleek and modern—more like a futuristic tool than a hobby project.

The enclosed build chamber on these machines serves a few functional purposes in addition to improving the aesthetics. Some materials, such as ABS and ASA, don’t print well without a high ambient temperature, so these materials can only be printed with an enclosed machine.

The enclosure also helps limit the spread of odors into the room, and although 3D printing is not typically associated with strong smells, this can be an advantage if you’re using your printer in a space with someone who is sensitive to the smell. Both printers include an air filter on the enclosure exhaust fan to further filter out odors.

Finally, the enclosure can help keep curious children or pets from interfering with ongoing prints. Unfortunately, neither printer will automatically stop printing when the enclosure door is opened, which would be a nice feature to see in the future.

Print Speed

The Creality K1 Max and Bambu X1C both advertise very fast print speeds — up to 600 mm/s for the K1 Max and up to 500 mm/s for the X1C. Both machines advertise a maximum acceleration of 20,000 mm/s3. These speeds are class-leading for FDM 3D printers, letting you spend less time waiting for your models to finish printing.

From the specs, it might seem like the K1 Max is notably faster than the X1C, but in practice, this is unlikely to be the case. The reason we refer to these specs as maximum speed, rather than just speed, is because either printer’s ability to actually hit those speeds is based on the geometry of the model being printed as well as what filament type is being used. The fact is, neither printer will hit these maximum speeds all the time, or even most of the time. They’re much faster than other 3D printers, though.

Extruder and Hotend

The K1 Max and X1C both include a direct drive extruder paired with an all-metal hotend capable of heating to 300℃, which enables them to print all standard 3D printing filament types. We like to see direct drive extruders—they’re more reliable than Bowden extruders, are less likely to cause stringing, and significantly improve the printer’s ability to print with flexible filament such as TPU.

One difference between the machines is in how the hotend is constructed. On the Creality K1 Max, the nozzle screws into the hotend body, which allows you to replace the nozzle or swap it for a different size without replacing any other components. On the other hand, the Bambu X1C’s hotend body and nozzle are one piece, meaning that you must replace part of the hotend when you replace the nozzle. Although Bambu Lab sells the replacement part for a low price, it’s not as cheap as replacing the nozzle on the K1 Max.

Material Support

The Creality K1 Max and Bambu X1C support all standard 3D printing materials, including common options such as PLA, PETG, and TPU, as well as more exotic filament types such as carbon fiber-reinforced PLA and nylon. Because both machines have an enclosed build chamber, they’re able to print materials such as ABS and ASA that require a high ambient temperature to print well.

For printing abrasive materials such as carbon fiber-reinforced PLA, you may want to get a hardened steel nozzle for the K1 Max to prevent the nozzle from wearing down prematurely. The X1C does include a hardened nozzle by default. You can pick up a set of hardened nozzles for the K1 Max in various sizes for a low price.

Firmware Improvements To Increase Print Quality

The K1 Max and X1C both include newer firmware optimizations that improve print quality, such as vibration compensation, pressure advance, and input shaping. These features first debuted in open-source firmware projects such as Klipper, but we’ve started to see more manufacturers adding them into their newer 3D printers to improve print quality. Especially at the high print speeds of both printers, these features can substantially improve the surface finish of printed parts.

In general, we expect the print quality of the machines to be similar. Bambu Lab has more experience with these firmware improvements and they’ve been pushing the limits of speed and quality since they first got into 3D printing, but Creality has been catching up quickly and now has a number of printers that implement these same improvements.

Setup and Bed Leveling

Unlike some lower-cost 3D printers and most older models, both the K1 Max and X1C arrive fully assembled and are nearly ready to print out of the box. Because 3D printers are precision devices, there is always some calibration required to level the print bed and prepare for use, but this is a quick, automated process on both machines.

Both printers include automatic bed leveling, which is becoming a common feature on printers across all price points. Additionally, the K1 Max and X1C both include a Lidar sensor to confirm the bed leveling settings, which we’ll describe in a later section.

Overall, these are some of the easiest 3D printers to set up and start using, no matter your level of experience. This is one area where paying more money for a premium machine definitely gives you a smoother user experience.

Display and Controls

The K1 Max and X1C both include a full-color graphical touchscreen controller which allows you to control the printer and monitor the status of ongoing prints. The display and controls are an area where 3D printers have been continually improving, and in our experience, a touchscreen is the simplest and best controller available.

We also appreciate that both printers include a large, usable display. Some recent machines have either used a small, low-quality screen or omitted the screen entirely, with the expectation that users will interact with the printer using its companion smartphone or computer app. However, we’ve found that a physical display and integrated controls are easier and faster to use when you’re standing in front of the printer, so this is a feature we’re happy to see.

Camera

Both 3D printers have a camera integrated into the build chamber, allowing you to monitor your printer even when you aren’t in the same room. Both printers’ cameras support real time monitoring as well as the ability to create a timelapse of a print. This is a convenience feature that we really like to see. Although it’s generally recommended to not leave a 3D printer totally unattended during a long print, the camera gives you more peace of mind if you aren’t nearby.

Both printers also advertise AI fault detection features involving the camera, such as the ability to detect the common “spaghetti” printing failure, where the printer begins extruding filament into open space instead of onto the existing printed model. We don’t have thorough test results for these features to know whether they reliably detect failures, but if nothing else, it’s encouraging to see both Creality and Bambu exploring these features.

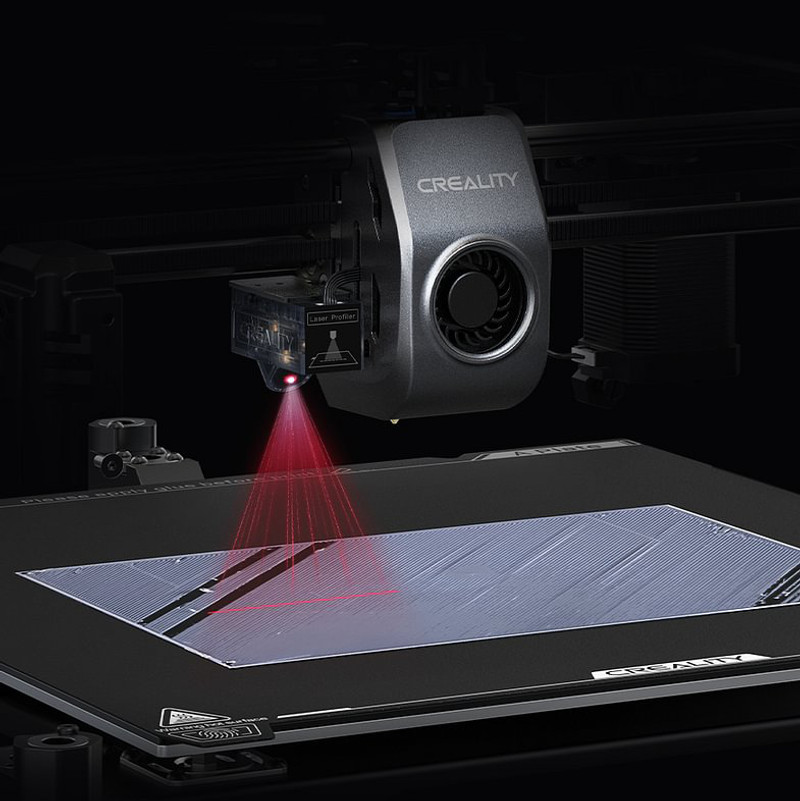

Lidar Sensor

The Creality K1 Max has matched one of the unique features Bambu brought to market with the X1C, which is a Lidar optical sensor that precisely measures the height of the first printed layer. This sensor allows both printers to detect whether the bed leveling and Z offset settings are correct, and help to ensure the first layer will be smooth and free of major imperfections.

This is a feature we’re really excited about, and we hope to see it included on more 3D printers in the future. Getting the first layer right is a major part of ensuring a successful print, so any features that improve that process are welcome.

The Bambu X1C does use its Lidar sensor for an additional level of calibration that the Creality K1 Max doesn’t yet match. As the first line of filament extrudes onto the bed, the X1C uses its Lidar sensor to measure the width and height of the filament, which allows it to calculate the correct flow rate multiplier for that filament. This allows it to automatically set the flow rate, which sometimes needs to be adjusted for new filament types and brands.

Next, we’ll look at the differences between the K1 Max and X1C.

Differences Between the Creality K1 Max and Bambu X1C

Although the K1 Max and X1C share many features, they have some important differences. We’ll cover each difference in this section and explain its impact.

Build Volume

One of the biggest differences between the Creality K1 Max and Bambu X1C is their build volume:

- Creality K1 Max: 300 x 300 x 300 mm (11.8” x 11.8” x 11.8”)

- Bambu X1C: 256 x 256 x 256 mm (10” x 10” x 10”)

At a glance, this may not seem like a major difference, but the K1 Max’s build volume is approximately 61% larger than the X1C’s. Even when only considering printing an object flat on the print bed, the 300 x 300 mm build plate on the K1 Max has the capacity to print larger objects than the 256 x 256 mm build plate on the X1C.

In our opinion, build volume is one of the first specs you should decide on when choosing a 3D printer. It’s not something you can usually upgrade after purchase, and although you can print a small object on a large 3D printer, you can never print a single object larger than the printer’s build volume. Even if you only intend to print small objects, a larger build volume would allow you to print more of them in a single batch.

It’s worth pointing out, though, that neither of these printers offers the largest build volume available in a consumer FDM 3D printer. Machines such as the Creality CR-M4 offer a substantially larger build volume than either the K1 Max or X1C, although truly large-format machines sometimes lack the advanced features found on these printers.

Physical Size

One downside to a large build volume is that the 3D printer must be physically larger. As a result, the K1 Max is a slightly larger machine than the X1C:

- Creality K1 Max: 435 x 462 x 526 mm (17.1” x 18.2” x 20.7”)

- Bambu X1C: 389 x 389 x 457 mm (15.3” x 15.3” x 18”)

The K1 Max is only a few inches larger than the X1C in each dimension, but if you’re in a particularly cramped workspace, its added size could be an issue for you. However, given the larger build volume on the K1 Max, it’s impressive that it’s as space-efficient as it is.

Bed Surface

The Creality K1 Max comes with a textured PEI bed, which is one of our favorite print bed materials. It provides good layer adhesion during printing, but easily releases the completed model once it cools down. This surface is generally durable and doesn’t require much maintenance. The bottom of the prints will have an orange peel texture due to the textured bed surface.

The Bambu X1C comes with two bed surfaces, a “cool plate” and an “engineering plate”. The cool plate is designed for printing PLA, TPU, and PVA filament at a low bed temperature of 35-45℃, while the engineering plate is designed for filament types that require a higher bed temperature. Both of these build plates have a smooth surface that will result in a glass-like surface finish on the bottom of the printed model, but both plates require you to coat the plate with a glue stick to aid in part adhesion, which is a bit annoying.

Both printers allow you to replace the included bed surface with a number of different options. For example, you can purchase a smooth PEI bed for the K1 Max, and either a smooth or textured PEI bed for the X1C. However, as far as the included bed surface with each machine, we prefer the textured PEI bed on the Creality K1 Max. It doesn’t require any additional adhesive to perform well, and is durable and reliable.

Connectivity and Software Support

Both 3D printers include wireless printing capabilities and allow you to control and monitor your prints using a smartphone or computer app. However, the specifics of which software is supported and how you can interact with the two printers is slightly different.

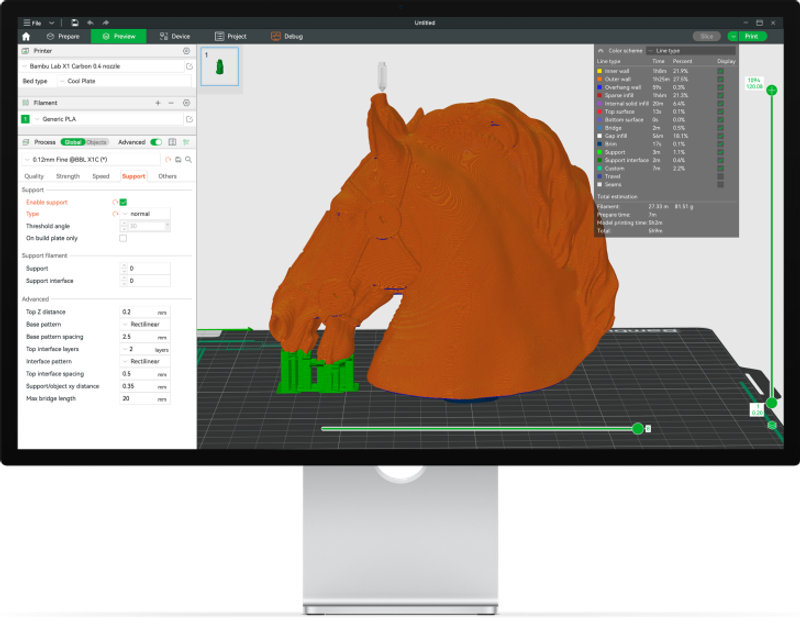

All of Bambu Lab’s 3D printers, including the X1C, have WiFi and allow you to connect to your printer using the Bambu Studio computer application or the Bambu Handy smartphone app. This is a core feature for Bambu and it’s clear that they expect users to use these apps to interact with their printers the majority of the time.

The Bambu Studio application includes a slicer, and although the X1C does support other slicers, you have to use the Bambu Studio slicer to take advantage of all of the X1C’s features. You can use the Bambu Studio application to upload gcode generated by other slicers wirelessly, but the X1C also has a microSD card slot for loading gcode to print.

The Creality K1 Max has WiFi as well as an Ethernet jack, giving you the ability to use a wired connection if you prefer. Similar to the X1C, you can control and monitor the printer remotely using the Creality Print computer application or the Creality Cloud smartphone app. However, unlike the Bambu X1C, it appears that all functions of the K1 Max are supported in both Creality’s own slicer software as well as third-party slicers. You can upload gcode files over WiFi, but the K1 Max also has a USB port which allows you to copy gcode files using a USB thumb drive.

Although we haven’t done a thorough comparison of each company’s software, we think Bambu Lab’s software is probably easier to use. It’s a core part of their 3D printer offerings, in comparison to Creality who has only recently expanded into the idea of app-controlled 3D printers. However, the Creality K1 Max allows you to take advantage of all of its features with third-party slicers such as Cura, which may be a benefit if you already have slicer software that you’re comfortable with.

Note that both companies offer the printer software for free, so you can download both the Creality Print software and the Bambu Studio software if you want to experiment with them before buying a printer.

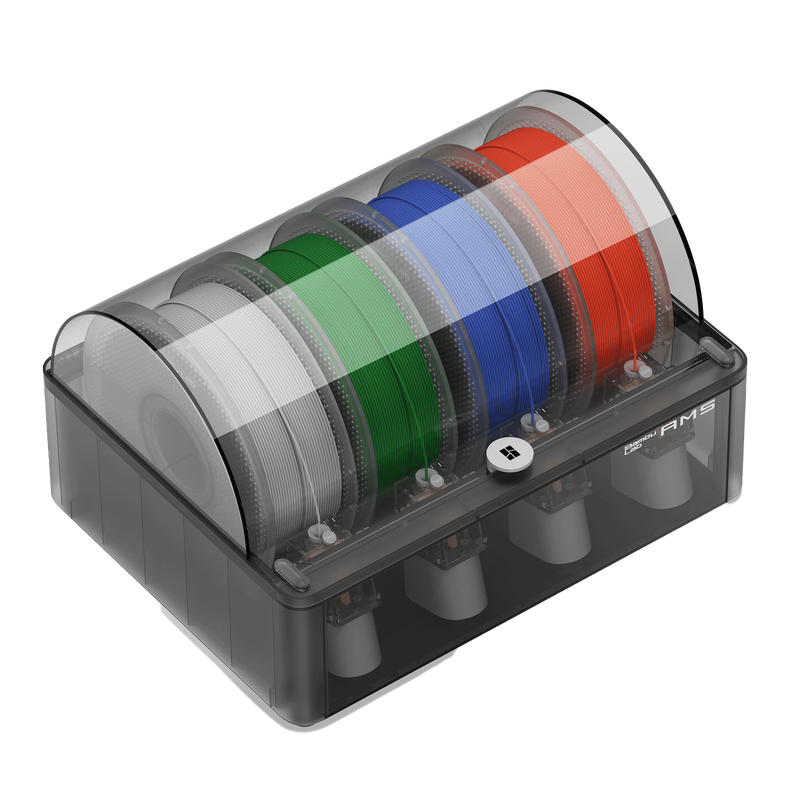

Multi-Material 3D Printing

The Bambu X1C supports Bambu Lab’s Automatic Material System (AMS), which is an add-on that allows you to feed up to four different types or colors of filament during a print. This enables you to print in multiple colors, as well as switch over to a new spool when one runs out of plastic, or print with soluble support material to make post-processing easier.

The AMS enables some exciting possibilities beyond what many other 3D printers can do, but it does have a few downsides. For one, it requires you to use the Bambu Studio slicing software rather than a third-party slicer. It also only works with normal size 1kg filament spools, so you won’t be able to use it with unusually large or small spools.

The Bambu AMS is available as a separate purchase from the Bambu Lab store, or you can purchase the X1C in a combo kit [Bambu Lab] that includes the AMS at a discounted price.

This is a feature that is unique to Bambu Lab’s 3D printers; the Creality K1 Max does not support the AMS.

Should You Buy The Creality K1 Max or the Bambu X1 Carbon?

The Creality K1 Max and Bambu X1-Carbon are similar in many ways, and it’s clear that Creality has aimed the K1 Max squarely at users who have been tempted by Bambu’s ease-of-use features, high performance printing, and sleek design. By all accounts, they’ve managed to design a printer that stands up well against the X1C, and exceeds it in some ways.

If you’re looking for a larger build volume or strongly prefer to use a third-party slicer, the Creality K1 Max will give you what you’re looking for. It also comes in at a substantially lower price than the Bambu X1 Carbon, leaving you more room in your budget for filament or other accessories. Given the cost savings, we feel that the Creality K1 Max is the better value between these machines.

However, if you want a slightly more polished software experience and the ability to upgrade to multi-material printing later, the Bambu X1 Carbon may be the better choice for you. Bambu also has a more established history with this set of advanced features, which may result in a more reliable printer.

Both of these 3D printers offer an impressive feature set and a level of polish that has been rare in the 3D printing market. They mark a shift in 3D printing from something that is only for committed hobbyists to a technology that anyone can take advantage of without needing to build expertise in calibration and troubleshooting. Although there are many more affordable 3D printers to choose from, if you have the budget for one of these machines, it’d be hard to go wrong with either the K1 Max or X1 Carbon.

Click here to view the Creality K1 Max on Amazon.

Click here to view the Bambu Lab X1 Carbon on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: