If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab X1-Carbon vs the Bambu Lab P1P

In this article, we’ll compare the Bambu X1C and P1P to help you understand how these two 3D printers are similar and different. We’ll explain why each difference may or may not matter for how you intend to use your printer, and give our recommendation of which one you should buy.

Bambu Lab X1 Carbon

(~10.25 x 10.25 x 10.25 in)

Vs.

Bambu Lab P1P

(~10.25 x 10.25 x 10.25 in)

Bambu Lab released the Bambu X1-Carbon 3D printer in the summer of 2022 and quickly gained a reputation for the printer’s high-end feature set, clean design, and unprecedented print speeds. The biggest downside to the X1-Carbon was its high cost, which put it in a higher price tier than what some users were willing to pay.

Bambu Lab addressed this a few months later with the release of the Bambu P1P, a much more affordable version of the X1-Carbon. The P1P obviously has a reduced feature set to save on cost, but has proved to be a popular machine in the 3D printing community regardless. Today, Bambu Lab still sells both printers, giving users the choice between a premium machine with all of Bambu’s signature features and a lower-cost machine that still has a high-end feel.

As a side note, many users refer to the X1-Carbon as the X1C. For simplicity, we’ll be using that abbreviation for the rest of this comparison.

Similarities Between the Bambu X1C and P1P

Although the Bambu X1C and P1P are in different price tiers, they have a surprising number of shared features. We’ll cover the similarities between the printers in this section.

Build Volume

The X1C and P1P both have a 256 x 256 x 256 mm (10” x 10” x 10”) build volume, which is slightly larger than the 220 x 220 x 250 mm build volume found on most consumer FDM 3D printers. This means that you can print the same size models on either machine.

In our experience, this size of build volume is appropriate for most 3D prints, and it’s big enough for some functional parts in addition to artistic models. However, if you need to print large parts, there are other 3D printers with much larger build volumes.

Print Speed

Both the Bambu X1C and P1P advertise a maximum print speed of 500 mm/s and a maximum acceleration of 20,000 mm/s. These speeds are some of the highest found in consumer 3D printers, and it’s surprising that Bambu Lab has made the lower-cost P1P match the X1-Carbon on this spec.

To achieve the high print speed, both printers use the same CoreXY motion system which is optimized for fast movement and quick direction changes. They also incorporate several firmware features to maintain print quality at higher print speeds, such as vibration compensation and pressure advance.

Direct Drive Extruder and All-Metal Hotend

The X1C and P1P both use a direct drive extruder, which we prefer over the Bowden extruders found on some other 3D printers. In our experience, direct drive extruders are more reliable and cause less stringing. They also significantly improve printing with flexible filament, such as TPU.

Both printers also include an all-metal hotend capable of heating to 300℃, which is sufficient for all standard 3D printing filament types.

Although they use the same extruder and hotend, the X1C and P1P do differ slightly in what materials you can print with since the P1P doesn’t have an enclosure. We’ll discuss that further in the Differences section below.

One downside to the hotend on both printers is that the nozzle is integrated with the hotend itself, meaning you have to replace the hotend if you want to replace the nozzle or change to a different nozzle size. This is an annoyance, and we wish the nozzle was independently replaceable. Fortunately, you can buy the nozzle/hotend assembly from the Bambu Lab store for a low price.

Connectivity and Software Support

Both printers include WiFi connectivity, allowing you to control and monitor your printer from the Bambu Studio computer application or the Bambu Handy smartphone app. The X1C and P1P also both have a built-in camera to monitor the status of prints, although the X1C’s camera is higher resolution.

The Bambu Studio application also acts as slicing software to allow you to prepare models for 3D printing. Although both printers do support third-party slicers such as Cura, you’ll need to use the Bambu Studio slicer to take advantage of all features of the printers.

AMS Compatibility

The X1C and P1P are both compatible with Bambu Lab’s Automatic Material System (AMS), which is an add-on that allows you to feed up to four different types or colors of filament during a print. This enables you to print in multiple colors, as well as switch over to a new spool when one runs out of plastic, or print with soluble support material to make post-processing easier.

The AMS enables some exciting possibilities beyond what many other 3D printers can do, but it does have a few downsides. For one, it requires you to use the Bambu Studio or Orca Slicer slicing software rather than a third-party slicer. It also only works with normal size 1kg filament spools, so you won’t be able to use it with unusually large or small spools.

The Bambu AMS is available as a separate purchase from the Bambu Lab store, or you can purchase the X1C in a combo kit [Bambu Lab] that includes the AMS at a discounted price. There isn’t a combo kit for the P1P, so you’ll need to purchase the AMS separately to use it with that machine.

Next, we’ll look at the differences between the Bambu X1C and P1P.

Differences Between the Bambu X1C and P1P

As you might expect, there are some meaningful differences between the X1C and P1P. We’ll discuss each one in this section and give you our opinion about which ones might matter to you.

Lidar Sensor

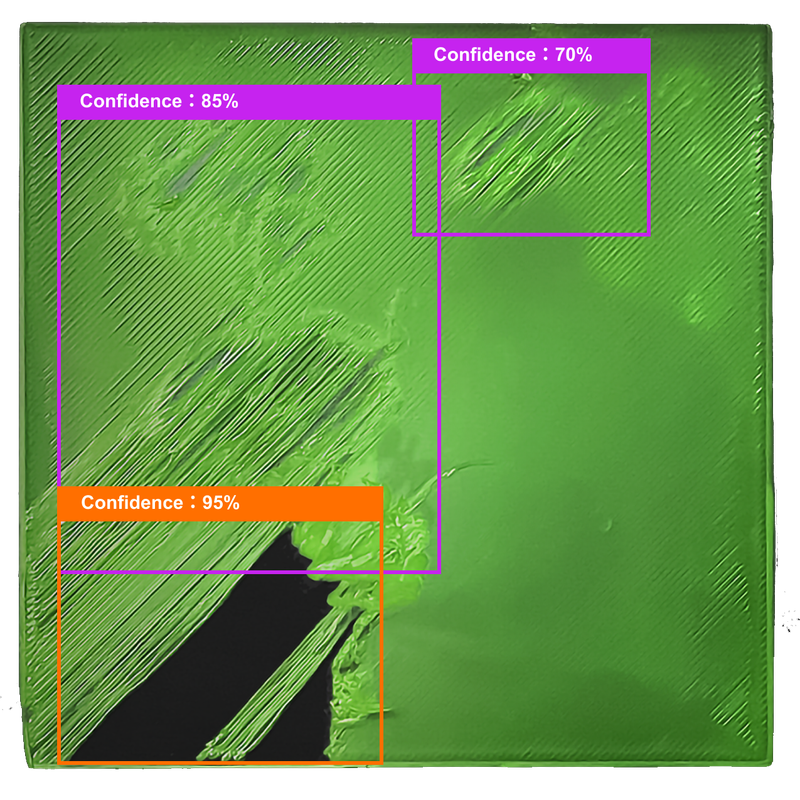

The Bambu X1C includes a Lidar sensor, which isn’t included in the P1P or any of their other 3D printers. This sensor enables a few interesting features that should improve the print quality of the X1C.

First, the Lidar sensor acts as a second automatic bed leveling sensor. While both the X1C and P1P include a force sensor for mechanically detecting the bed height, the X1C additionally uses the Lidar sensor to optically detect the bed height to further verify the bed leveling results. It can also detect the height of the first layer when the model begins printing, allowing the printer to confirm the Z offset height. If the bed is poorly leveled and the first layer isn’t coming out well, the printer can stop the print rather than wasting time and material.

Second, the Lidar sensor can analyze the height and width of extruded filament on the first layer, allowing it to calculate the flow rate of the filament. When you’re using non-Bambu filament, this feature allows the X1C to automatically calibrate the flow rate of the filament for maximum print quality.

These are features that aren’t found on most other consumer 3D printers, and they should make the Bambu X1C slightly more reliable at automatic bed leveling and perform slightly better when using a variety of filament brands or types. It will also give you more confidence that the first layer of your print is coming out well. However, we’ve seen consistent, reliable results from many other 3D printers that don’t have the Lidar sensor, so we consider this more of a nice-to-have feature than a key improvement.

Enclosure

The X1C has an enclosed build chamber, with metal sides and a glass top and front door. This seals the build chamber during printing, which allows the X1C to maintain a higher ambient temperature and limits the smell associated with 3D printing. In contrast, the Bambu P1P has an open-frame design that is not enclosed.

The main benefit to the X1C’s enclosure is that it allows you to print materials such as ABS and ASA that require a higher ambient temperature. These materials do not print well without an enclosure because the printed parts need to maintain a consistent temperature–if they’re cooled unevenly, the parts can warp or delaminate along layer lines. The X1C includes a temperature sensor inside the build chamber and circulates air as needed to maintain a consistent temperature.

Additionally, the enclosure reduces the smell that sometimes occurs during 3D printing. While FDM 3D printing does not typically cause a strong smell, certain materials such as ABS can give off an odor that some users find unpleasant. The X1C incorporates an activated carbon filter on the exhaust fan to filter out these odors, which may make it a desirable choice if you’re sensitive to these smells or share your printing space with someone who is sensitive to it.

Finally, the enclosure provides a degree of protection from curious children or pets. Although the Bambu X1C doesn’t stop printing when the door is open, the enclosure itself can prevent accidental or intentional interference with an ongoing print.

In our opinion, the enclosure is a notable improvement of the X1C over the P1P. Even if you don’t plan to print ABS or ASA, the enclosure gives you the capability to do so if you change your mind in the future. Additionally, it reduces some of the sound and smell associated with 3D printing. However, it’s worth noting that if you have a Bambu P1P, you can purchase an upgrade kit from Bambu Lab to add an enclosure. You could also purchase the Bambu P1S, which is essentially a P1P with an enclosure.

Build Surface

The X1C and P1P come with different print bed surfaces, although they’re both compatible with the full set of bed surface options offered by Bambu Lab.

The X1C comes with two build plates, a “cool plate” and an “engineering plate”. The cool plate is designed for printing PLA, TPU, and PVA filament at a low bed temperature of 35-45℃, while the engineering plate is designed for filament types that require a higher bed temperature. Both of these build plates have a smooth surface that will result in a glass-like surface finish on the bottom of the printed model, but both plates require you to coat the plate with a glue stick to aid in part adhesion.

The P1P comes with a textured PEI build plate which is suitable for all filament types and is more durable than the two build plates included with the X1C. Textured PEI offers very good part adhesion, and its only downside is that it leaves an orange peel-like texture on the bottom of printed models.

Between these options, we prefer the textured PEI build surface that comes standard on the Bambu P1P. Textured PEI is one of our favorite bed types to work with, and we’ve consistently seen good results when using it. Of course, it’s worth noting that Bambu Lab sells the textured PEI bed separately, and it’s a fraction of the overall cost of the Bambu X1C, so this probably shouldn’t prevent you from buying the X1C if you’re otherwise more interested in that machine.

Display and Controls

The Bambu X1C and P1P provide significantly different integrated displays and physical controls. The X1C uses a 5” graphical touchscreen, which allows you to easily monitor and control the printer. This is a modern approach that we’re starting to see on more and more consumer 3D printers, and we appreciate the usability of a touchscreen.

On the other hand, the Bambu P1P uses a comparatively rudimentary monochrome display that can only display text and icons, along with an arrangement of physical buttons. While we don’t have any issues with the buttons, the display feels outdated and doesn’t fit the otherwise premium feature set of the P1P.

While the WiFi connectivity of both printers gives you the ability to monitor and control the printer from your smartphone or computer, we still appreciate the integrated controls on our 3D printers. When you’re in the room and want to quickly check on a print or manually move the printer, it’s just easier to use the controls on the machine. The X1C clearly wins in this category and feels much more modern to interact with than the P1P.

Camera

While both the Bambu X1C and P1P include a camera mounted inside the build chamber, the camera in the X1C is notably better than the one in the P1P.

The X1C’s camera is 1080p resolution and can stream at 30 frames per second, allowing you to monitor the status of an ongoing print in real time. It also can generate a timelapse of the print, and includes an AI-powered feature which purports to detect “spaghetti”, which is a common print failure where filament begins extruding into open space instead of being attached to the rest of the printed model.

On the other hand, the P1P’s camera is only 720p and can only stream at 0.5 frames per second. This is still useful for remote monitoring, but it’s not a smooth livestream. The P1P does support the timelapse feature, but does not support the AI failure detection feature of the X1C.

The X1C clearly wins in this category, but these camera improvements don’t affect print quality and are only a small improvement in usability. It is nicer to see ongoing prints in higher quality, and the AI fault detection may save you from a long failed print and the associated waste of material, but even the lower resolution camera on the P1P gives you more ability to monitor ongoing prints than what you get with most other machines. No matter what monitoring features you have, it’s always best to not leave a 3D printer completely unattended during a print, and you should always check on the printer periodically to ensure things are still running smoothly.

Should You Buy The Bambu X1C or P1P?

Although the Bambu X1C and P1P are clearly in different price tiers and have several notable feature differences, what’s surprising is how similar the two printers are. In most ways, the Bambu P1P matches the printing capabilities and quality of the X1C, while coming in at a much lower price.

The Bambu X1 Carbon is undoubtedly one of the most advanced FDM 3D printers you can buy, with features such as the Lidar sensor and AI camera fault detection setting it apart from most of the competition. The enclosure enables printing with all standard filament types, and its high print speeds and advanced firmware features make it a great choice of printer if you’re willing to spend more money for a better machine. You do get what you pay for over the P1P in some regards, such as the greatly improved display and the higher resolution camera.

However, the Bambu P1P offers the same core features related to print speed and quality, and is capable of printing most of the same filament types as the X1C. If you need to print with filament types that require an enclosure, you can purchase an enclosure upgrade for the P1P, or spring for the Bambu P1S. Most of the X1C features it lacks are usability or quality-of-life improvements, so you won’t be missing out on major printing capabilities by going with the P1P.

Overall, our recommendation is to go with the Bambu P1P over the Bambu X1 Carbon unless you really want the extra sensors and ease-of-use features the X1 Carbon offers. Bambu has done an admirable job of bringing the most important features from the X1 Carbon down to a more affordable price point, with the P1P giving you most of the benefits of a Bambu Lab printer at an approachable price.

The Bambu X1 Carbon and P1P are only available for purchase directly from the Bambu Lab website:

Click here to view the Bambu Lab X1 Carbon on the Bambu Lab website.

Click here to view the Bambu Lab P1P on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: