If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab P1P vs the Creality K1

In this article, we’ll compare the Bambu Lab P1P and Creality K1 to determine how these two 3D printers are similar and different, and help you decide which printer is the best choice for you.

Bambu Lab P1P

(~10.25 x 10.25 x 10.25 in)

Vs.

Creality K1

(~8.75 x 8.75 x 10 in)

Comparing the Bambu Lab P1P vs Creality K1

Bambu Lab only started producing their first 3D printers in June 2022, but they quickly gained a following in the community with their reputation for extremely high print speed, sleek designs, and advanced features not seen on other machines. By the end of 2022, they had released the Bambu P1P, a more affordable model that has since become a go-to recommendation for many 3D printing hobbyists and small businesses.

Creality, as one of the more established 3D printer manufacturers, has taken notice of Bambu Lab’s success and has released the Creality K1 to compete with it. The K1 seems to be a clear response to the Bambu P1P, offering many of the same features at the same price. The question is, which printer is better?

Similarities Between the Bambu Lab P1P and Creality K1

The P1P and K1 have many features in common and share many of the same capabilities. We’ll describe each one in this section and explain how they contribute to the performance of each printer.

High-Speed Printing

Both the Bambu P1P and Creality K1 are capable of extremely high print speeds that match or surpass other consumer FDM 3D printers. This is one of the primary selling points of both printers, and it’s a meaningful improvement over many other 3D printers. The faster print speed results in shorter printing times, which reduces one of the biggest frustrations in 3D printing.

The Creality K1 advertises a maximum print speed of 600 mm/s, while the Bambu Lab P1P advertises a maximum print speed of 500 mm/s. Both printers advertise a maximum acceleration of 20,000 mm/s2. These are some of the fastest print speeds we’ve ever seen for consumer FDM 3D printers.

Although the K1’s maximum speed is faster than the P1P’s maximum speed, we don’t expect you to notice this difference in use, so we dont consider this a notable difference. Maximum print speed is a misleading spec because the geometry of the printed model will affect how often the 3D printer is actually able to attain its maximum speed. Many precise details, as well the bottom and top layer of the model, have to be printed at slower speeds to maintain high print quality. You’re likely to perceive the K1 and P1P as having a similar print speed in normal operation.

The two printers implement similar hardware and software features to achieve their high print speed, which partially explains why the two machines are so similar. It also contributes to the higher cost of these printers over some of their competition.

Motion System

Both printers have a cubic frame design that encloses the machine within a metal frame, unlike the more open gantry frame design used by most other consumer 3D printers. The enclosed frame design is more robust and maximizes rigidity, which helps to reduce vibration at high print speeds. However, the primary reason for this frame design is that both the P1P and K1 use a CoreXY motion system.

The CoreXY motion system uses two stationary motors mounted to the frame, which takes weight off the print head. A system of pulleys and serpentine belts allows these motors to move the print head in both the X and Y axes at high speed. Unlike the more common Cartesian motion system, the print bed doesn’t move in the X or Y axis on a CoreXY system–it only moves up and down. At the beginning of the print, the print bed will be raised to its highest position, close to the print head. As the print progresses, the bed slowly moves downward. This design decreases vibration by not having to move the heavy print bed back and forth during printing.

Both manufacturers have used the CoreXY motion system on multiple printer models–Bambu Lab uses it on the X1C, P1P, and P1S, and Creality has used it on a few of their previous machines such as the Ender 6 and Ender 7. Although it’s less common, CoreXY is a well-understood motion system design and we don’t have any concerns about how it’s implemented on either machine.

Extruder and Hot End

The P1P and K1 both include a direct drive extruder, which is beneficial for several reasons. This type of extruder is faster and more reliable than a Bowden extruder, and improves the printer’s ability to print flexible filament such as TPU. We’re happy to see Bowden extruders starting to go away because direct drive is preferable in almost all cases.

Both printers also include an all-metal hotend that can heat up to 300°C, which is hot enough to print all common 3D printing filament types, including high-temperature filament such as nylon. The printers do have a few small variances in their supported filament types, which we’ll cover in the Differences section, but these differences are due to the enclosure on the K1, rather than any difference in the hotend design.

There is one small difference in the hotend between the two machines. On the Bambu P1P, the hotend and nozzle are one piece, which means you have to replace that entire piece if you need to replace the nozzle or want to switch to a different nozzle size. On the other hand, the Creality K1 has removable nozzles like most other 3D printers we’ve seen. Bambu Lab does sell hotend/nozzle replacements for the P1P on their site for an affordable price, but the K1’s replacement nozzles are cheaper.

Print Bed Surface

Both printers include a textured PEI bed surface, which is one of our favorite 3D printer bed surfaces. This material offers good adhesion while the bed is heated, but releases prints easily when cooled. The surface can be easily replaced on both printers because it attaches magnetically to the print bed.

Firmware Features to Improve Print Quality

The Bambu Lab P1P and Creality K1 both include firmware features such as pressure advance, input shaping, and vibration compensation to improve print quality at high print speeds. These features are starting to appear on more premium 3D printers and make a meaningful difference in print quality. They allow the printer to compensate for the mechanical stresses that come into play at faster print speeds, and manage the extrusion of plastic more precisely to make layer lines more uniform and cleaner.

Bambu arguably has more experience with these algorithms since they’ve been including them from the start, but Creality seems to have based their firmware on the open-source Klipper project, which has seen significant development from the 3D printing community and is well-regarded. In our experience, both manufacturers’ firmware is capable of producing excellent prints, and these features are likely a contributing factor to that quality.

Automatic Bed Leveling

Both printers include sensors for automatic bed leveling and filament runout detection, which have become common features on modern 3D printers.

Automatic bed leveling is a key feature that enables the printer to detect the height of the bed and compensate for any uneven portions of the bed during the print. This greatly improves the consistency of prints and automates a calibration step that used to be time-consuming. Both the P1P and K1 use a strain sensor for automatic bed leveling, which touches the nozzle to the bed to detect its height. In our experience, this is the best and most reliable form of automatic bed leveling. Other approaches which use seperate sensors such as BL-touch require setting a “Z-offset”, which describes the difference in height between the sensor and height. A strain based system actually measures using the nozzle itself, so it is a more direct and less error prone approach.

Filament Runout Sensors

Filament runout detection allows the printer to pause the print if it detects that the filament spool has been depleted. We’ve had mixed feelings about this feature. It can be useful if you’re nearby and able to quickly deal with the issue, but if you aren’t near the printer, this can fail the print. In the case of Creality, the print bed cools down when a filament runout condition is detected, causes the print to release from the bed and makes it impossible to resume printing.

Differences Between the Bambu P1P and Creality K1

While the P1P and K1 share many features, they also have some key differences that may affect which of these printers is more compelling for you. In this section, we’ll explain each difference and what impact it has on the experience of using each 3D printer.

Enclosure

One immediately apparent difference is that the Creality K1 has an enclosed build chamber, while the Bambu Lab P1P does not. The enclosure offers a few benefits. Most importantly, it enables the K1 to print materials such as ABS and ASA that require a high ambient printing temperature. These materials tend to not print well without an enclosure; they can warp upward at the corners, or may even crack in half along layer lines when printed in open air. The enclosure keeps the printed model at a consistent temperature and prevents it from cooling unevenly.

Additionally, the enclosure can help prevent curious children or pets from interfering with an ongoing print. However, the K1 doesn’t include a door sensor to pause the print when the enclosure door is opened–this is a feature we’d like to see added in a future version of the printer.

One thing to note about enclosed 3D printers is that while you’d expect them to be quieter than their non-enclosed counterparts, they aren’t much quieter in reality. The enclosure can help reduce the sound of the print cooling fans, but the enclosure itself has an exhaust fan to keep the temperature within reasonable limits, so you simply trade one fan sound for another. The motor noise, while quiet, tends to still transmit through the frame of the printer to the desk surface and enclosure walls, so even enclosed printers are not silent.

The Bambu P1P doesn’t come with an enclosure, but you do have a few options to add one. Bambu Lab provides free STL files that you can use to 3D print side walls for the P1P, which provides some amount of protection from air drafts in addition to allowing you to personalize the machine. If you want to go all the way to a fully enclosed machine, Bambu Lab sells a kit to upgrade the P1P to a P1S, which is enclosed. Or, you could buy the Bambu Lab P1S, which is essentially a P1P with an enclosure.

Build Volume

The two printers have build volumes that are similar but not identical in size:

- Bambu Lab P1P: 256 x 256 x 256 mm (10.1” x 10.1” x 10.1”)

- Creality K1: 220 x 220 x 250 mm (8.6” x 8.6” x 9.8”)

This means the Bambu P1P can print slightly larger objects than the K1, although the difference is small enough that you may not notice. This is the most common build volume size class for consumer printers, and is a good balance between being able to print a variety of different models and functional parts, while not taking up too much desk space.

If neither printer’s build volume is sufficient for your printing needs, you may want to consider the Creality K1 Max, which is a K1 with a larger 300 x 300 x 300 mm (11.8” x 11.8” x 11.8”) build volume and a few other premium features such as a Lidar sensor and integrated camera.

Material Compatibility

Although the P1P and K1 can both print many of the same 3D printing materials, they have a few discrepancies.

Both printers can print the most common filament types, including PLA, PETG, and TPU, and a few less common types such as PET, PVA, PA, and PC. For many use cases, this is more than sufficient–for example, many 3D printer owners only ever use PLA. However, if you need to print with ABS or ASA, the enclosure on the K1 will make it much more capable of printing these materials than the P1P; you’d need to add an enclosure to the P1P to print these materials successfully.

Both printers advertise support for carbon fiber-infused filaments, such as PLA-CF. However, because the carbon fibers are abrasive, you should consider upgrading to a hardened steel nozzle if you want to print these materials frequently. Neither printer comes with the hardened nozzle, but both Creality and Bambu Lab offered hardened nozzle options separately. You can find hardened nozzles for the Creality K1 on Amazon, or a hardened nozzle/hotend for the Bambu P1P on Bambu Lab’s website.

Display and Controls

The Bambu P1P has a basic monochrome text and icon-only display with a set of physical button controls. While we don’t have an issue with the buttons, the display feels uncharacteristically cheap compared to the rest of the printer. It’s harder to read than a graphical display, and only gives you the bare minimum of information. For example, one thing we found frustrating about the P1P’s display is that you can’t see a preview–or even an estimated print time–for any gcode files stored on the printer’s SD card, making it sometimes difficult to remember which model you want to print from the card.

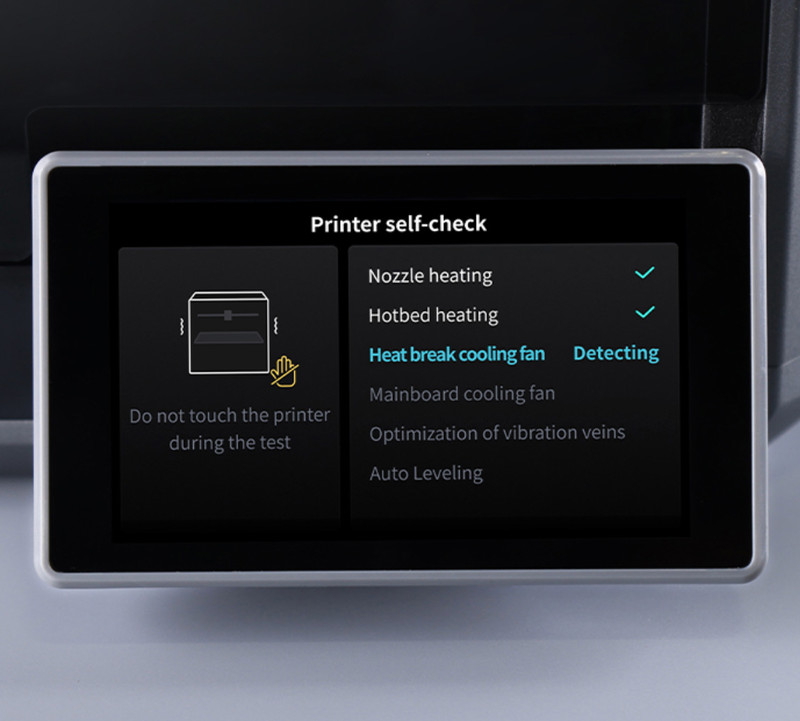

The Creality K1 includes a 4.3” graphical color touchscreen controller, which has a much more modern feel and is much easier to use. We prefer the usability of touchscreens, and Creality’s user interface is easy to use while giving you more information about the status of the printer than the Bambu.

It’s clear that Bambu expects users to monitor and control the P1P using the phone app, but we wish they hadn’t used such a basic screen on the P1P. This is an area where the K1 definitely has the advantage.

Connectivity and Software

Both 3D printers include WiFi for wireless printing and support both computer and phone apps, but the specific software support on each printer is different.

The Bambu Lab P1P supports the Bambu Studio computer application and the Bambu Handy smartphone app. Both of these apps allow you to control and monitor the P1P over WiFi, including viewing its integrated camera. The Bambu Studio app includes slicer software, which allows you to prepare a 3D model for printing and send it directly to the printer. We’ve been happy with Bambu’s slicer so far, but it’s worth noting that Bambu says you need to use their slicer to take advantage of all of the P1P’s features–so you may notice some shortcomings if you use a third-party slicer such as Cura.

If you don’t want to use WiFi, the Bambu Lab P1P also has a microSD card slot which you can use to load .gcode files to print, just like most other 3D printers.

The Creality K1 supports the Creality Print computer application and the Creality Cloud web app and smartphone app. These apps allow you to control and monitor the K1 over WiFi. The Creality Print application includes a slicer to allow you to prepare a 3D model for printing and send it directly to the K1. In contrast to Bambu, Creality doesn’t make any statements about lesser support for third-party slicers. While you’d need to use the Creality Print to upload your gcode wirelessly to the printer, you could use any slicer to prepare that gcode with no compatibility issues.

If you don’t want to use WiFi on the K1, you can plug a USB drive into the printer to transfer gcode files onto it.

We don’t really have a preference between these options, but you may find that you like one company’s software more than the other. Fortunately, you can download and try both Bambu Studio and Creality Print without purchasing a printer.

Camera

One interesting feature included on the Bambu P1P is an integrated camera in the build area, which allows you to monitor the status of prints from the Bambu Studio computer application or Bambu Handy phone app. The camera isn’t especially high quality, and annoyingly, it has a very low framerate of 0.5 FPS, but it’s enough to let you keep an eye on an ongoing print even if you aren’t in the room. You can also configure the camera to automatically create a timelapse video of the print, which is a fun feature.

The Creality K1 doesn’t include a camera, although it does support an “AI Camera” add-on [Amazon link] which adds similar functionality.

Multi-Material Support

The Bambu P1P supports Bambu Lab’s Automatic Material System, or AMS, which is an add-on that allows you to feed up to four different types or colors of filament during a print. This enables you to print in multiple colors, as well as switch over to a new spool when one runs out of plastic, or print with soluble support material to make post-processing easier.

The AMS enables some exciting possibilities beyond what many other 3D printers can do, but it does have a few downsides. For one, it requires you to use the Bambu Studio or Orca Slicer slicing software rather than a third-party slicer. It also only works with normal size 1kg filament spools, so you won’t be able to use it with unusually large or small spools.

The Bambu AMS is available as a separate purchase from the Bambu Lab store, and it’s only supported by Bambu Lab’s printers–the Creality K1 doesn’t offer a similar multi-material printing option.

Community

One interesting difference between the printers is the user community. While both manufacturers have vibrant online communities, the Bambu P1P is a particularly popular 3D printer and has a massive community of enthusiasts who discuss modifications and print settings for the P1P. If you’re the type to want to participate in an online user group focused on your printer model, the Bambu P1P is probably one of the most popular machines out there.

On the other hand, while Creality generally has a large user community, the K1 is a less commonly-discussed machine. Many Creality users were attracted to the brand several years ago for their low-cost, easily-modified machines, and not all of them are interested in the more polished K1. While you’re likely to still find some discussion of the K1 online, there is less of a community presence for it as compared to the Bambu P1P.

Should You Choose the Bambu Lab P1P or the Creality K1?

The Bambu P1P and Creality K1 both offer an impressive feature set that is far beyond the 3D printers of a few years ago. These machines are faster, more reliable, and produce better-looking 3D prints than almost any other consumer FDM 3D printer on the market today, and it’s hard to go wrong with either machine.

The Bambu P1P offers a slightly larger build volume than the K1, and includes a camera in the build chamber that we found convenient for monitoring ongoing prints. Bambu has built a reputation for making printers that are easy to use, and in that regard, we were very impressed with the P1P: it was one of the easiest setup experiences we’ve had with a 3D printer, and the software is easy to use and works well. You also have some interesting upgrade options with the Bambu P1P, such as the ability to add an enclosure or the AMS system for multi-material printing.

However, the Creality K1 also has a few points in its favor. It includes an enclosed build chamber, as well as a much more modern and usable touchscreen display. Repair parts such as nozzles are available for a lower price than Bambu Lab’s equivalents, and the K1 more readily supports third-party slicer software. Creality has been making 3D printers for several years now, and we’ve always been pleased with the longevity of their machines, so we have reason to trust the K1. In most ways, it offers similar or better capabilities than the Bambu P1P and is typically available at a lower price point, which makes it an attractive option.

Click here to view the Bambu Lab P1P on the Bambu Lab website.

Click here to view the Creality K1 on Amazon.

You can find a side-by-side comparison of the specifications for these two printers in the table below: