If you make a purchase using a shopping link on our site, we may earn a commission. Learn More

Comparing the Bambu Lab P1P vs the Bambu Lab A1 Mini

In this article, we’re going to compare the Bambu Lab P1P to the A1 Mini to help you determine which of these 3D printers is the right choice for you. We’ll look at where the printers are similar, as well as the differences between them, and give you our recommendations for which features to pay attention to when making your decision.

Bambu Lab P1P

(~10.25 x 10.25 x 10.25 in)

Vs.

Bambu Lab A1 Mini

(~7.25 x 7.25 x 7.25 in)

Bambu Lab announced the A1 Mini in the fall of 2023, bringing a new low-cost model to their lineup of 3D printers. With an unconventional design and many of Bambu Lab’s hallmark performance-related features, the A1 Mini immediately got attention as an affordable entry into 3D printing.

With pricing that significantly undercuts the Bambu P1P, we’re all curious to see how these two printers compare. Does the A1 Mini easily unseat the P1P as the most cost-effective Bambu 3D printer, or does it remove too many of the features that have made the P1P so popular?

We’ll start by covering the similarities between the printers.

Similarities Between the Bambu P1P and A1 Mini

The Bambu P1P and A1 Mini share a few key similarities, especially in terms of their supported filament types and connectivity. We’ll cover each in this section.

Print Speed

High print speed has always been a headlining feature of Bambu Lab’s 3D printers, and both the P1P and A1 Mini advertise a maximum print speed of 500 mm/s. The printers do differ in maximum acceleration, with the A1 Mini topping out at 10,000 mm/s2, which is half of the P1P’s acceleration limit. However, we’d expect the printers to offer very similar print speed in real world use.

Both printers have a set of key firmware features that help to maintain print quality at higher speeds, such as vibration compensation and pressure advance. Hardware also plays a part in maximum speed, but the P1P and A1 Mini do differ in that respect, so we’ll cover that in the Differences section below.

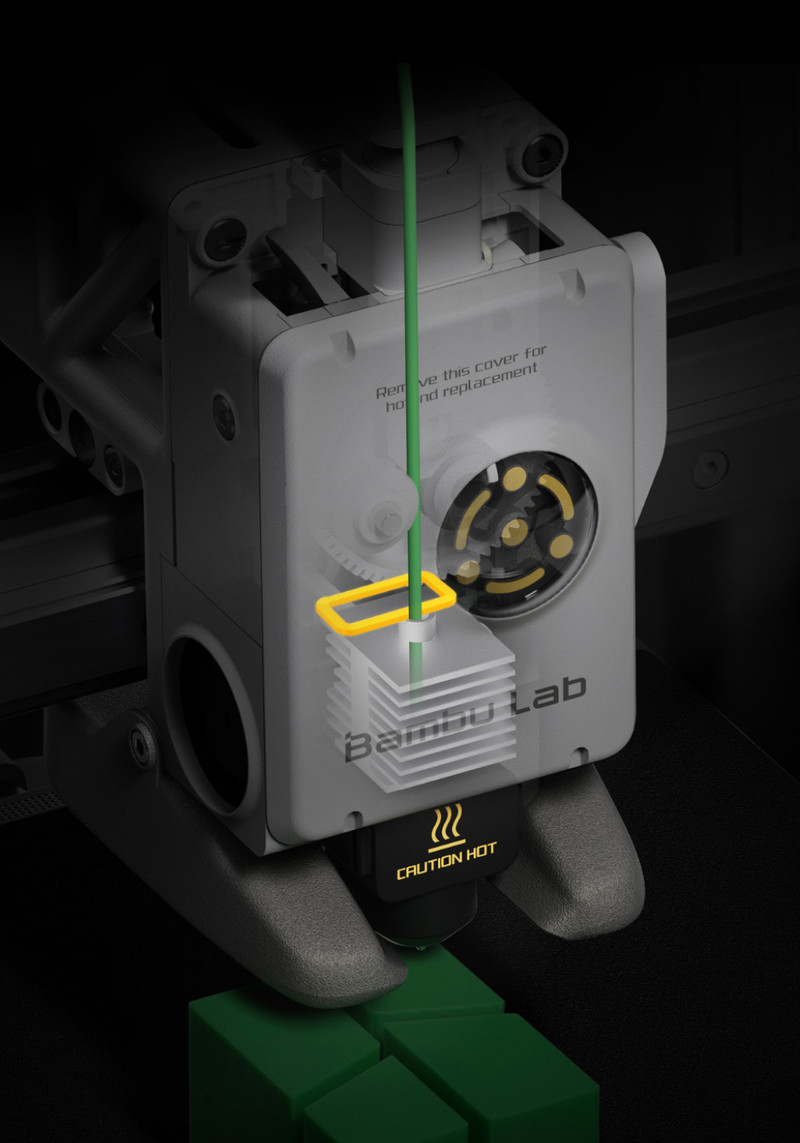

Direct Drive Extruder and All-Metal Hotend

The P1P and A1 Mini both include a direct drive extruder and an all-metal hotend which enables them to print many common filament types, including flexible filament. The hotend can heat up to 300℃, which is sufficient for almost every 3D printing filament type.

The two printers do have slightly different hotend designs, but they share one key disadvantage. On both machines, the nozzle is integrated into the metal hotend assembly, requiring you to replace the hotend if you want to replace the nozzle or change to a different nozzle size. This feels a bit wasteful, and while the hotends are available on Bambu Lab’s store for a low price, it’s still more expensive than purchasing nozzles for most other 3D printers.

The A1 Mini does have a newer hotend design which can be replaced more easily than the hotend on the P1P, which is a welcome change.

Supported Filament Types

Because the P1P and A1 Mini have similar hotends and both lack an enclosure, they support a similar set of filament types, including PLA, PETG, TPU, and PVA. Many users only ever use these materials, with PLA being by far the most common, so you may never need to print with filament types other than these.

The A1 Mini does have a slightly lower maximum temperature of only 80℃ for its heat bed, in comparison to the P1P which can heat its print bed to 100℃. This doesn’t make a difference for the standard materials supported by either printer, but it would come into play if you were to print a material such as ABS, which generally requires a heat bed temperature of 100℃.

However, because neither printer is enclosed, the P1P and A1 Mini are unlikely to print materials such as ABS and ASA successfully, since these filament types require a high ambient temperature to print well. If you want to print these materials on the P1P, you’d need to purchase the P1S upgrade kit from Bambu Lab. For the A1 Mini, you might be able to use a third-party enclosure to completely surround the printer, but you’re likely to run into other problems, such as the electronics of the printer heating up during the print. If you want to print ABS or ASA, you’re better off getting the P1P with an enclosure, or the Bambu P1S.

Bed Surface

Both the P1P and A1 Mini come with a flexible textured PEI build plate, which is one of our favorite print bed materials. It offers good first-layer adhesion during printing, but easily releases prints once it cools down. In addition to the textured PEI surface, both printers are also compatible with other build plate options from Bambu Lab, including a smooth PEI surface. Since the printers have different build volumes as described in the Differences section of this comparison, the build plates themselves are not interchangeable between the two machines.

Connectivity and Software Support

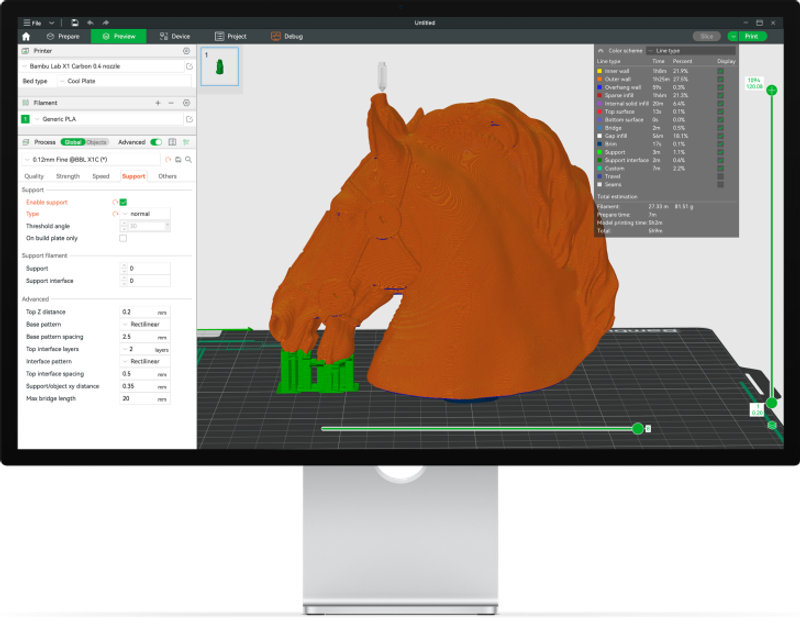

The P1P and A1 Mini both include WiFi support to allow you to monitor and control your 3D printer remotely using the Bambu Studio computer application or the Bambu Handy smartphone app. These applications allow you to track the status of ongoing prints as well as starting a new print, and you can even view the print using the integrated camera on either printer.

The Bambu Studio computer application also has integrated slicing software for preparing 3D models. You can use a third-party slicer such as Cura if desired, but Bambu cautions that third-party slicers may not support all of the advanced features of their printers.

Next, we’ll discuss the differences between the two 3D printers.

Differences Between the Bambu P1P and A1 Mini

You can tell by looking at the Bambu P1P and A1 Mini that they’re different in several ways, but some of the differences may surprise you–the P1P isn’t necessarily the better printer in every way, even though it’s more expensive. We’ll cover each of the differences and give you our analysis about how it should affect your decision.

Build Volume and Size

The two printers have fairly different build volumes:

- Bambu P1P: 256 x 256 x 256 mm (10” x 10” x 10”) build volume

- Bambu A1 Mini: 180 x 180 x 180 mm (7.1” x 7.1” x 7.1”) build volume

This is a meaningful difference between the machines and will affect what items you’ll be able to print on each. The 256 mm build volume on the P1P gives plenty of breathing room for larger models or functional parts, while the smaller 180 mm build volume on the A1 Mini may feel limiting for certain types of parts. Depending on what you want to print, the smaller build volume may not be an issue for you, but it’s worth thinking about what types of models you want to print and ensure you purchase a 3D printer that will be able to handle models of that size.

On the other hand, a printer with a larger build volume is generally larger in physical size, and for this reason, the A1 Mini is noticeably smaller than the P1P:

- Bambu P1P: 386 x 389 x 458 mm (15.2” x 15.3” x 18.8”) size

- Bambu A1 Mini: 347 x 315 x 365 mm (13.7” x 12.4” x 14.4”) size

This size difference may not sound significant, but if you’re trying to fit your 3D printer into a small space such as a dorm room or cluttered workbench, the A1 Mini will have a smaller desk footprint. There are clear tradeoffs to be made between the P1P and A1 Mini in build volume vs. physical size.

Motion System

The P1P and A1 Mini use different motion systems, which is one of the most distinctive visible differences between the machines.

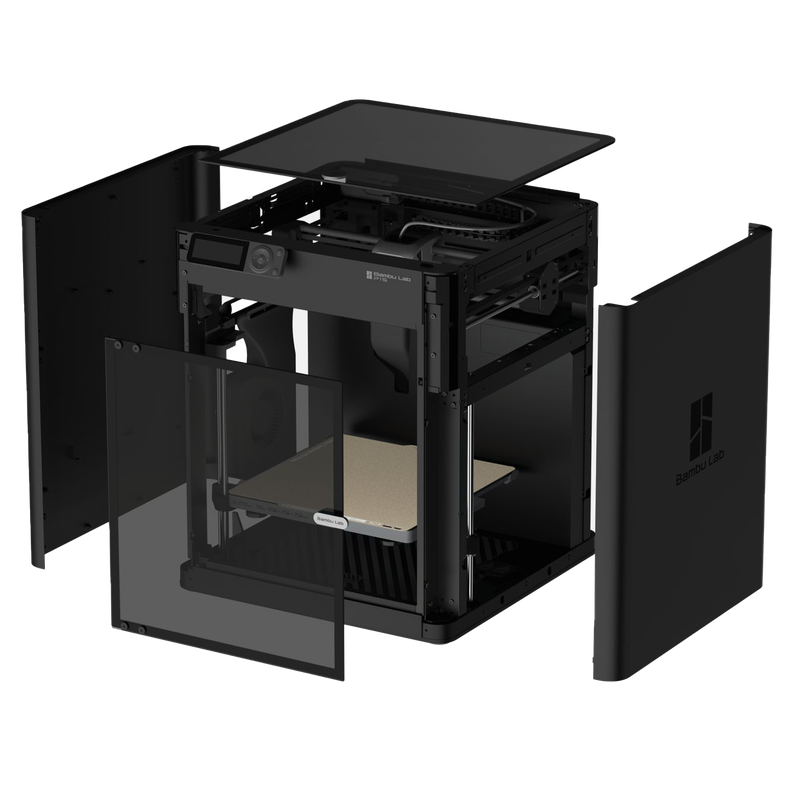

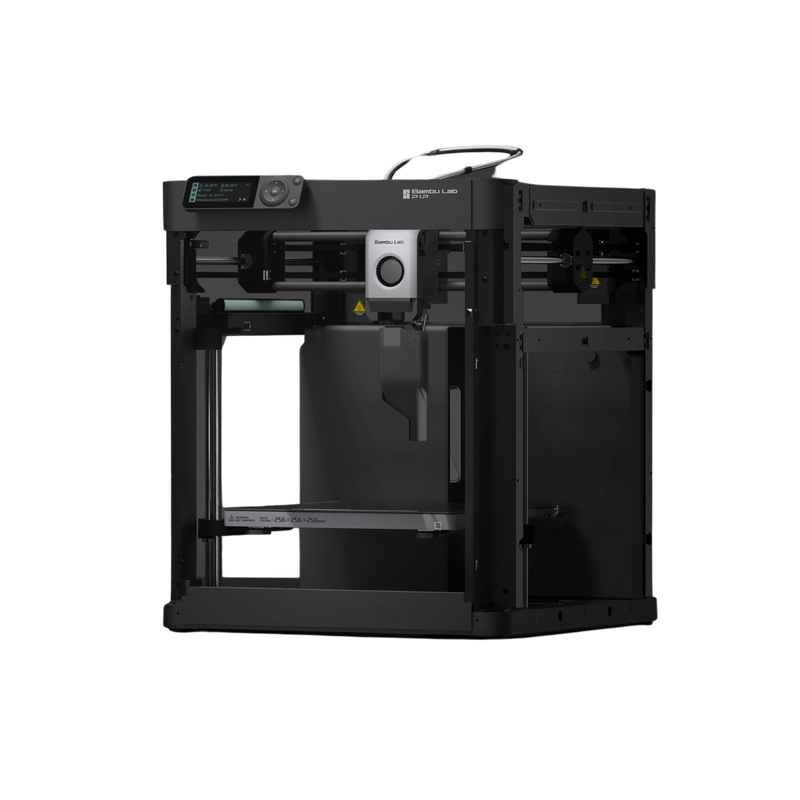

The P1P is built inside a cube-shaped metal frame, and uses a CoreXY motion system that is optimized for high print speed and rapid direction changes. This is a proven design that Bambu Lab and other manufacturers have used on a number of high-performance 3D printers. A side benefit to this design is that the metal frame lends itself well to being enclosed, and Bambu Lab offers an upgrade kit to add an enclosure to the P1P.

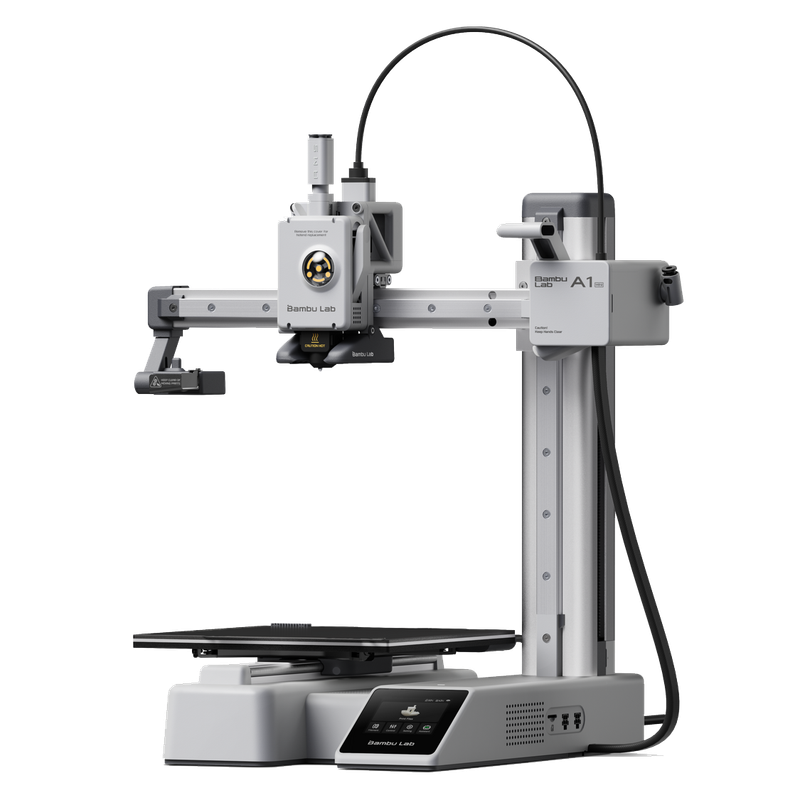

The A1 Mini uses a Cartesian “bed slinger” motion system, but with a less conventional design that supports the X axis with only a single Z column. We’ve seen this design on a few other 3D printers at similarly low price points, but the other machines with this design typically have not offered print speeds anywhere close to the 500 mm/s advertised by Bambu Lab for the A1 Mini. They did incorporate linear rails for all three movement axes, which should decrease vibration at higher print speeds.

Between these two designs, we prefer the CoreXY motion system on the P1P. It’s a more proven design, and we appreciate that the metal frame of the P1P helps enclose the moving parts of the printer. The A1 Mini’s motion system seems well-designed for a Cartesian system with a single Z column, but we can’t help but feel that it’s fighting the forces of physics more than the P1P to hit its advertised print speeds.

Flow Rate Compensation

The Bambu A1 Mini includes a sensor for measuring the flow rate of the filament that is surprisingly more advanced than what the higher-priced P1P offers. This sensor is located in the hotend and uses eddy currents to measure the current flow rate of the filament through the nozzle, which allows the printer firmware to compensate for any unexpected variance in the filament flow. This promises to reduce one of the settings that you typically have to calibrate in your slicer software for each filament type and brand you use.

Bambu Lab uses the Lidar sensor on their premium X1 Carbon model to achieve a similar goal, but the P1P doesn’t offer this feature at all, and the flow rate sensor on the A1 Mini is a new design that we haven’t seen before on any 3D printer. We’re curious to test this for ourselves to see how well it works, but it’s one area where the A1 Mini clearly improves on the P1P.

Filament Tangle Sensor

While both printers include common fault-detection features such as a filament runout sensor and power loss recovery, the A1 Mini includes a new filament tangle sensor that measures the tension on the filament to pause the print if the spool gets tangled and stops feeding into the printer. This is a failure scenario that isn’t detected by a normal filament runout sensor, and since it’s a common cause of failed 3D prints, we’re excited to see this type of sensor on a printer.

Display and Controls

The display and controls are another category where the Bambu A1 Mini surprisingly exceeds the capabilities of the P1P. Not that the P1P was setting a high bar–we were disappointed at its monochrome text-and-icon-only display, and felt that it was one of the few rudimentary features on an otherwise premium 3D printer.

In contrast, the Bambu A1 Mini includes an integrated graphical touchscreen, which allows you to easily interact with the printer and monitor the status of ongoing prints. The screen is smaller than the large touchscreen found on the Bambu X1C, but its graphical touchscreen will be easier to see and use than the text-only screen on the P1P.

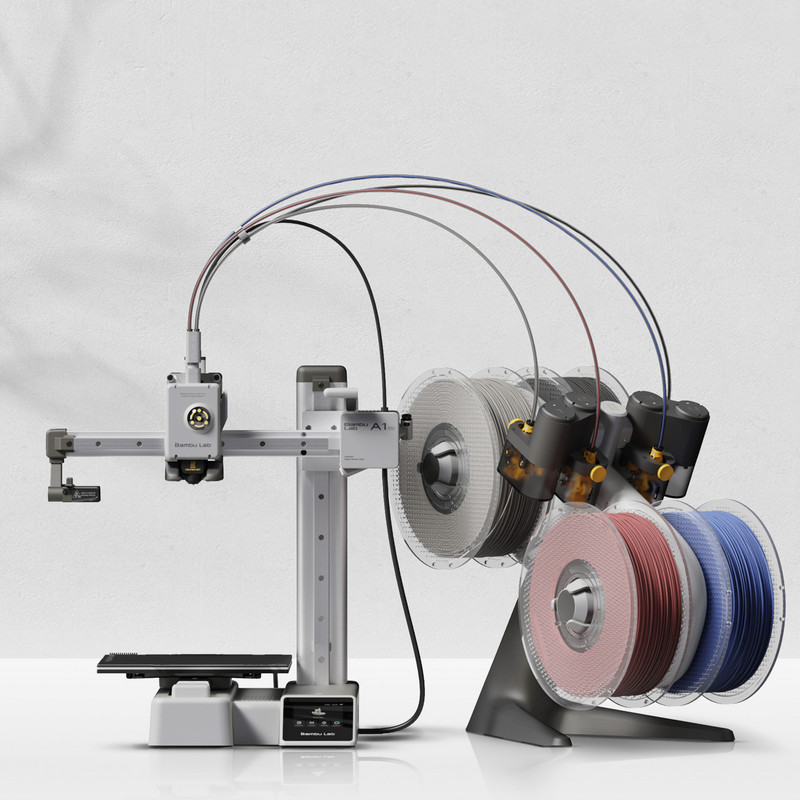

AMS Compatibility

The Bambu Automatic Material System (AMS) is an add-on for Bambu Lab’s 3D printers that allows the printer to feed from multiple rolls during a print. This allows for multicolor 3D printing, but also enables capabilities such as switching to a new roll when one roll runs dry, or printing support material with a different material that is soluble or easier to break away from the print.

While the P1P and A1 Mini both support the AMS capabilities, the two printers support different AMS units.

The P1P supports the existing Bambu AMS, which fits on top of the printer and holds 4 rolls of filament in an enclosed box. The AMS is available as a separate purchase from Bambu Lab’s store.

The A1 Mini supports a new variant, known as the AMS Lite. The AMS Lite doesn’t have the sleek, integrated design of the larger AMS, but its design makes it compatible with more types of filament spools, which may be an advantage depending on which filament brands you prefer. It’s also available as a separate purchase from Bambu Lab’s store, as well as in a combo kit with the A1 Mini.

The main downside to both the AMS and AMS Lite is that they only work with the Bambu Studio slicer software and the open-source Orca Slicer software–you won’t be able to use other slicers if you want to take advantage of the AMS.

Should You Choose the Bambu P1P or the Bambu A1 Mini?

The Bambu P1P and A1 Mini offer some interesting tradeoffs. The P1P scores immediate points for its larger build volume, ability to add an enclosure, and more robust motion system. However, the A1 Mini comes in at a much lower price, has a better integrated display, and includes some new sensors and capabilities not found on the P1P.

Both printers offer Bambu’s signature set of modern capabilities, such as WiFi connectivity, real time monitoring with an integrated camera, and class-leading print speeds. In some ways, the printers couldn’t be more different, but in others, they’re surprisingly identical.

Our opinion is that most users will eventually appreciate the added capabilities of the P1P. Its build volume is notably larger, and while you can always print smaller objects than a printer’s maximum build size, you can’t ever really upgrade the build volume without buying a new printer. And even if you don’t envision needing to print ABS or ASA filament now, the P1P can more readily support an enclosure if your needs change in the future.

On the other hand, if you’re wanting to test the waters of 3D printing or need a machine that is as compact as possible, the Bambu A1 Mini is one of the most advanced and capable small 3D printers we’ve ever seen. Beyond the small build volume, you really aren’t giving up much in terms of features, and in some ways, the A1 Mini’s feature set outclasses that of the P1P. If we were buying a 3D printer for a dorm room or cramped workshop, we’d definitely lean toward the A1 Mini.

Both the P1P and A1 Mini are only sold on Bambu Lab’s store. You can check out both printers using the links below.

Click here to view the Bambu Lab P1P on the Bambu Lab website.

Click here to view the Bambu Lab A1 Mini on the Bambu Lab website.

You can find a side-by-side comparison of the specifications for these two printers in the table below: